CNC control upgrade of a floor-type mill

The US automation system integrator MasterControls LLC Inc. (MCI) selected NUM’s technology for the refurbishment of the CNC system on a large floor-type horizontal boring mill made by Gray.

Destined for a major machinery remanufacturer operating in the mining industry, MCI and its rebuilder customer performed a very extensive electrical and mechanical rebuild on the mill - even adding a secondary x-axis. The machine had originally been converted from manual to CNC operation back in the 1970s, but the control system was primitive by today’s standards, with numerous drawbacks including limited CNC functionality, a very small memory size, and no networking capability.

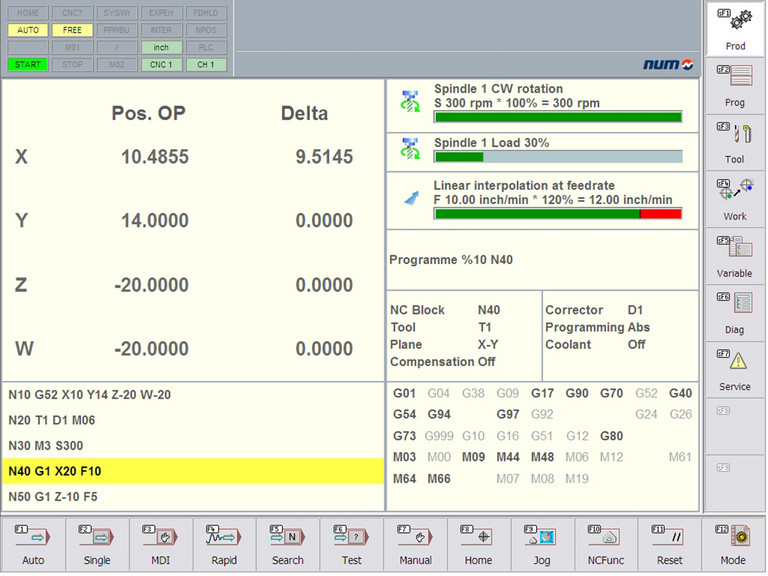

By choosing a NUM CNC kernel, MCI has been able to deliver major enhancements to the mill’s CNC functionality. These include compatibility with RS274 G-code programming, probing functionality, and an industrial PC front end providing unlimited program storage - as well as networking capability.

MCI’s introduction of a tandem drive arrangement on the x-axis has made a major contribution to the machine’s performance and accuracy, increasing torque dramatically for the main axis of the machine - which weighs over 100’000 pounds (>45’000 kg). The two axes are now synchronized in a master-slave arrangement, with the new secondary axis set to lag the primary axis very slightly in order to maintain tension in the geartrain and eliminate backlash. The flexibility of the drives and control software that allowed this configuration was another important reason behind MCI’s decision to base the upgrade on NUM technology, as its drives support master-slave architectures.

As this was a critical element of the project, MCI visited NUM’s facility in Naperville, Illinois during the development of the control system to physically test the tandem control, as well as to get the CNC vendor’s feedback on MCI’s proposed control and programming scheme. Improving the underlying precision and accuracy of the heavily-built mill was a major feature of the control system upgrade, and MCI additionally implemented a table with laser measurements of axis positions to compensate for other variations in the mechanics.

Another key factor in choosing NUM’s CNC system was the ability to upgrade the servo drives to advanced digital operation with absolute feedback - enhancing precision a step further. This also eliminated the need for homing moves - freeing the user from having to reference the machine on power loss or after shutdown. All of the control system engineering and panel building was done off site. When the retrofit control system was complete, MCI took the package to the customer rebuild site and started the installation. This phase was achieved in just three days. After testing and training, the whole machine was then disassembled and shipped to the end user.

According to Jeff Petry, MCI’s Owner & Managing Partner, “We go to our customers with code that has been tested for reliability. The technical support available from NUM, who partner with us on applications like this, makes us comfortable taking on these types of complex projects.”

MCI has become well known throughout the United States for automation upgrades on machine tools. The system integrator has over 25 years experience in the business, replacing legacy CNC systems on lathes, mills, grinders, gear hobbers and other capital equipment. One reason behind MCI’s large share of the USA machinery rebuilding market is its willingness to retain existing analog-interfaced servomotor drives on CNC systems - for economy - although this was not a factor in this latest project where the demand was for optimum precision. In turn, MCI relies on close relationships with a number of reliable control system equipment partners, including NUM for CNC applications. If the choice of CNC technology is left to MCI, the system integrator typically chooses NUM because of the programming flexibility the system provides, and the company’s willingness to provide in-depth technical support.

“Strong engineering support, and a partnership approach has always been a major element of NUM’s business philosophy,” adds Steve Schilling, General Manager of NUM Corporation in Naperville. “It’s one of the reasons behind the company’s success with small to mid-sized machine tool OEMs, and system integrators and upgrade specialists such as MCI.”

(March 2011)