50 years of experience and the courage to further strengthen the company

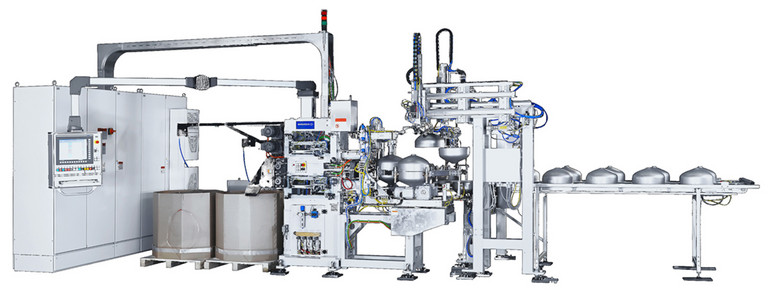

Based on many years of experience in resistance welding, Soutec AG from Neftenbach near Winterthur is equipping the first fully automatic welding plant for disposable drinks containers with a NUM control system.

Following an order from a leading producer of kegs, Soutec is manufacturing the world's first fully automatic welding system for disposable containers, which will feature a NUM control system.

For the first time in the history of drinks packaging, it has been possible to make disposable packaging which is both ecologically and economically superior to conventional re-usable packaging. The costs for returning, cleaning, repairs and logistics incurred by the reusable kegs are significantly higher than those for the new disposable kegs, which can be recycled anywhere in the world.

To keep the containers as light as possible, the material is just 0.4 mm thick. This is sufficient to meet the safety standards related to bursting pressure. The form of the steel containers only becomes stable when the two halves are welded together, and the capacity of the kegs is 30 litres. One of the requirements for the production plant and therefore the NUM control system was that after the machine stops, in whichever position, they automatically resume operation without the intervention of the operating staff.

Two of the most important requirements for the production plant were overall manufacturing times, as well as safe handling of the upper and lower halves of the container and reliable execution of the welding. Because of the thin walls and the resulting instability, this presented a great challenge for the plant and the NUM control system.

Soutec has been using NUM control and drive systems for many years in its machines and plants. The innovative company from Neftenbach has always broken new ground in the field of laser welding for complex components such as tailored blanks or pipes. Revolutionary concepts and ideas followed by professional implementation have ensured that the company is the world leader in some areas and thus guaranteed its future. It is an ideal partner for NUM.

(October 2009)