Achieving a competitive edge by short response times, innovation and advanced development - as well as precision production

Hofmann-Vratny is one of the leading manufacturers of solid carbide tools, with its production headquarters in Assling near Munich, and another facility, the re-sharpening center, in Nuremberg. The company can look back on a successful 40-year corporate history characterized by continuous growth. With NUMROTO, NUM has played a significant role in the development and production of milling tools and drills at Hofmann-Vratny for around 22 years. Nowadays, it is impossible to imagine a production company that does not use milling as a production method. For machining workpieces quickly and precisely, Hofmann-Vratny relies on modern CNC machining centers, the majority of which are equipped with NUMROTO. At present, about 1.6 million tools are produced each year.

The core product range offered by Hofmann & Vratny primarily includes solid carbide milling tools. In the 1980s, the company was one of the first to launch these tools on the market. Today, the manufactured products include micro-tools for the medical and semiconductor industries, and high precision milling tools for mechanical engineering, aerospace technology and, last but not least, the automotive industry.

“With the help of very close and long-term cooperation with partner companies such as NUM AG, carbide suppliers and coating companies, as well as by quick response times covering everything from inquiries for a new application to the delivery of the appropriate tool, Hofmann & Vratny has managed to position itself in the premium tool grinding segment”, says Marius Heinemann-Grüder, CEO at Hofmann & Vratny.

Hofmann & Vratny produces tools for the aerospace and automotive industry, as well as for the medical sector. At present, great emphasis is placed on the development of new CFRP tools (carbon-fiber-reinforced plastic), since this material is being increasingly widely used in production, especially in automotive construction. However, even tooling materials such as aluminum, titanium and sandwich materials for the aerospace industry are also enjoying an increasing demand. Even tools for machining tempered steel hardened to up to 75 HRC (Rockwell hardness) are no problem at all for Hofmann & Vratny.

In order to manufacture such special tools, you need motivated employees in addition to a good working environment. “The goal is that every employee looks forward to coming to work in the morning”, says Robert Wendl, the Production Manager at Hofmann & Vratny. In order to achieve this goal, the company makes large investments regularly. The new production hall with a heat recovery system and a UPS system has been commissioned recently in Assling. This enables a considerable part of the energy that is consumed for production to be recovered and thus saved. This helps to further reduce production costs in this fiercely competitive market. Hofmann & Vratny also invests regularly in the latest generation of CNC machines. On specific request, these are fitted with a NUM controller and NUMROTO software. “The advantage of NUMROTO is that it is easy to operate and can be deployed universally, and yet offers a large number of options for designing and manufacturing new and special tools” says Robert Wendl. “Even if something does not work out at the first attempt, an alternative solution is sought immediately by making a personal telephone call to NUM AG. Partnership based cooperation ensures that the problem is resolved promptly, in the minimum”, adds Wendl. At NUM AG they rely on good, intensive partnership with the customer and on the user-friendliness of the applications. As a result, a new employee engaged by a customer using NUMROTO can be trained quickly, and then deployed at various machines.

For standard, special and micro tools, the suitable machine can be procured, and still, all machines use the same programming system of NUMROTO. With the help of perfectly coordinated development and production processes, Hofmann & Vratny is in a position today of achieving production figures of 1.6 million tools per year, and producing a range of 7,000 different solid carbide tools for machining.

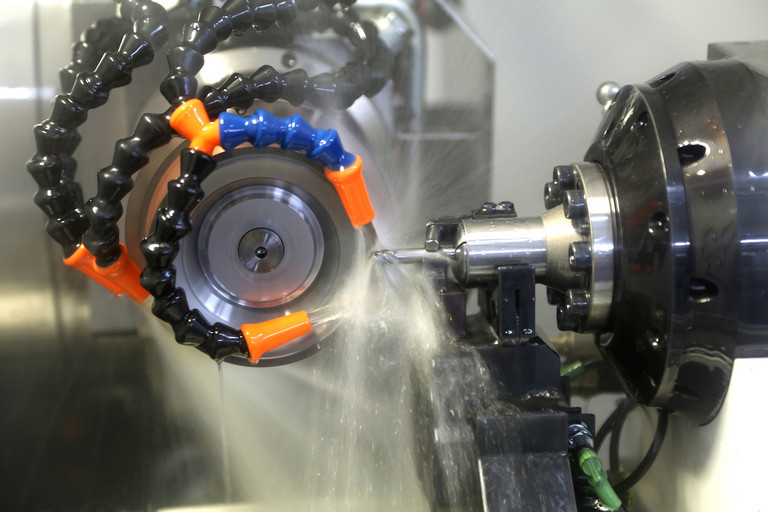

An example of the innovative and development strength of Hofmann & Vratny is the high-performance milling tool illustrated here. This diamond-coated milling tool is used within the automotive industry for machining CFRP and GFRP (glass-fiber-reinforced plastic) materials. Thanks to the special shape and the cooling ducts, the fibers are first pressed in one direction and then in the other, which causes them to tear without leaving residues and without fraying. As a result of the neat edge produced in this first work step, the next step of edge finishing is normally superfluous, which saves cost and time. This is a very significant factor under present day circumstances.

GFRP, CFRP and graphite end mills

By cutting in opposite directions, de-lamination of the top and bottom edge is prevented. Thanks to the simultaneous effect of the tensile and sliding forces on the cutter and the special arrangement of the cooling ducts, you achieve excellent results. In order to increase the service life, the tool is provided with the latest generation of diamond coating.

(September 2016)