CNC retrofit increases performance of vintage high end machine tool

Jean Gallay S.A. has been in business for over 100 years and is renowned for its high precision metal components. The company manufactures and repairs parts and assemblies for gas turbines, helicopter and fixed-wing aircraft engines, and nuclear reactors. Manufacturing these state-of-the-art parts requires sophisticated technical knowledge, irreproachable quality standards and know-how. That’s where NUM appears on the stage as a reliable partner in the field of CNC, to help increase the quality and productivity of CNC machine tools. Jean Gallay’s customers include such well-known companies as Alstom, Areva, Safran, MAN and Rolls-Royce.

Jean Gallay is a specialist in precise sheet metal work for manufacturing complex components for use in extreme operating conditions. The company applies outstanding technical expertise, stringent quality control and non-destructive testing to all stages of manufacturing. With over 180 employees, uncompromising standards are maintained at all times to ensure that Jean Gallay products and services achieve the highest levels of precision, quality and reliability.

Like NUM, Jean Gallay operates at the cutting edge of its chosen specialist field. It produces hot gas part sections/collectors, combustion chambers and injectors or burners for gas turbines. The company also manufactures components such as welded casings, honeycomb rings, diffusers and distributors.

The mission for the retrofit of this Duplo Standard CNC machine was not only to modernize the CNC control but also to increase the performance of the machine. Another key consideration was that the new Flexium CNC control by NUM needed to offer backwards compatibility with all the programs that Jean Gallay had developed and written for the machine during the past 20 years, so that they could continue to be used for production purposes in their present form. This is an inherent benefit of the Flexium platform and a significant advantage over competitive CNC systems. NUM’s Flexium CNC control system has enabled Jean Gallay to avoid spending many hundreds of hours rewriting all its production programs to suit the upgraded machine.

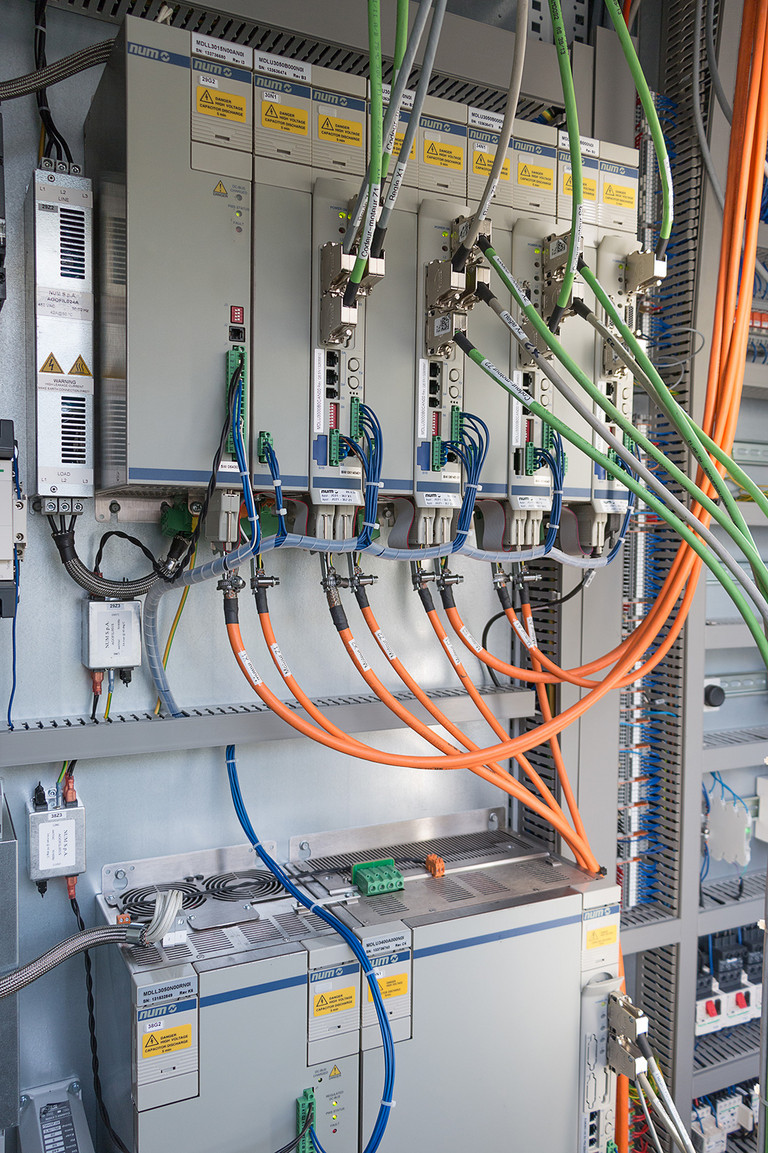

The CNC machine was retrofitted by NUM with the new Flexium CNC control unit. The machine has 7 axes and 2 spindles, which are powered by 9 NUM motors. With the new CNC control, the machine can be maintained online by NUM’s technical staff, in the event of a problem. This reduces machine downtime to a minimum, allowing 24h/day operation to maximize productivity.

As comparatively small to midsize companies in the global market, Jean Gallay and NUM set themselves apart from their larger competitors by means of continuous development, innovative solutions derived through close partnership, strong teams of highly qualified employees and excellent global service networks. These factors are also the basis for the success of the two companies. Saving time and resources by developing innovative production solutions, such as this machine retrofit, enables companies to be as competitive as the big players in the market.

This retrofit project again shows that a good machine, even if it was originally manufactured several decades ago, can be brought 100% up to date technically by a rebuild. The performance of a rebuilt machine is often as good as a new model – in some instances it may even be better due to a higher standard of basic construction – and this approach will cost significantly less than a new machine. Extending the lifetime of an existing machine by another 20 or more years makes sound economic sense, especially in today’s competitive market where production costs are becoming more and more important.

(October 2015)