High precision and flexibility thanks to NUMROTO

Whether in mechanical engineering, the automotive industry, electrical and medical technology or wood and plastics processing, the range of different tools used in an increasingly differentiated production environment seems endless. Mauth Werkzeug-Schleiftechnik GmbH is a long-standing NUM partner – it has been using NUMROTO for its highly specialist production for around 15 years.

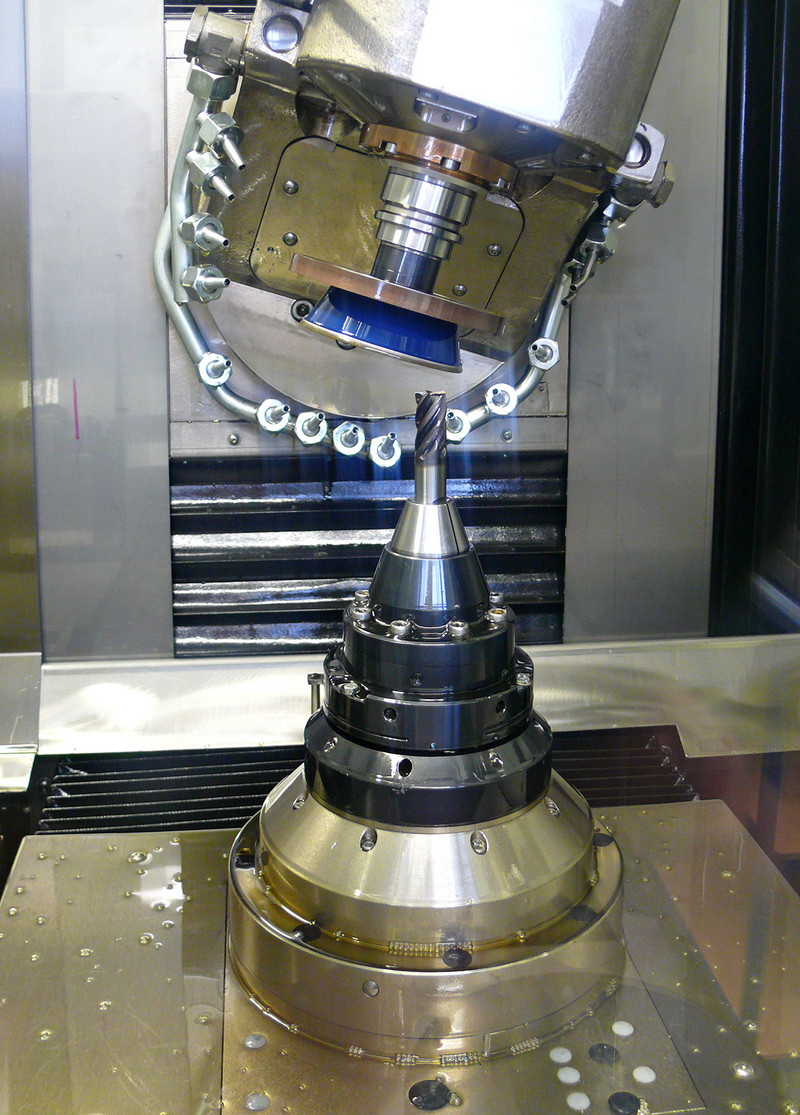

Mauth develops and produces perfect-fit tools in series, which meet exacting customer demands. Complex shapes are designed to specific measurements in the CAD system and loaded onto the CNC machines using NUMROTOplus. Whether it is a drill, an end-mill, a form cutter or a step drill, NUMROTO gets everything in shape and ensures a perfect finish. Mauth opted for NUMROTO around 15 years ago, following a market analysis which revealed that a NUM controller combined with NUMROTO software was difficult to beat in terms of flexibility and quality.

It is this quality and, more importantly, the flexibility which is so important to Mauth Werkzeug-Schleiftechnik GmbH. As all 16 tool grinding machines in the company are running on the NUMROTO multiuser system and are networked to a central system database, any employee trained in NUMROTO can operate all the machines. This guarantees continuity in the event of employee absence, and helps maximize productivity as employees do not need to wait for a particular machine to be available – they can simply move to a free machine and continue production.

Mauth Werkzeug - Schleiftechnik GmbH, which has a production area covering over 1000 square metres in Oberndorf am Neckar, is constantly increasing its fleet of machinery. In 2013, Mauth is adding another two machines to the fleet. “These new machines will also be equipped with NUMROTO,” explains Michael Mauth, Managing Director of Mauth Werkzeug-Schleiftechnik GmbH. This keeps the company at the cutting edge of technology. Measurement machines fitted with infrared and swivel cameras, as well as constant reconciliation of actual and target values, ensure consistently high process quality.

The connection between the measurement machine and the grinding centre adds more production accuracy, as does measurement of the rotary tools while they are turning – all controlled and monitored by NUMROTO. Most of Mauth’s customers are in Germany and its neighbouring countries, though it also has some in the USA and Asia. A sophisticated logistics system makes it possible, in exceptional cases, to produce tools and deliver them to the customer within 24 hours, even if the customer is based in Asia.

Mauth’s most precious asset is the expertise of its engineers and employees, based on 35 years of experience in metal processing. Its philosophy is the same as NUM’s, to offer ’maximum quality and perfection‘, and this ensures low error rates at both companies and great customer satisfaction. Continuous professional development is very close to the hearts of those at Mauth. NUM works together with innovative customers such as Mauth on targeted developments to achieve a competitive advantage. This is the only way that it is possible to produce standard and specialist tools with optimum precision, run-out accuracy and machining performance. Mauth works in the same way as NUM, in close proximity with its customers, thus providing the aforementioned flexibility and quality as well as problem-solving at the machine. This means that the customer’s workflow can be examined on site if required. Its know-how allows Mauth to optimise specific customer processes, which can mean cutting several seconds off the entire working process – and everyone knows what a few seconds can mean in modern series production.

Removable inserts – the complete solution

With the help of its inserts systems, Mauth can provide tools for internal and external processing – shaped removable inserts with one, two or three blades. Excellent replacement accuracy of under 0.01 millimetres and consistent repeat accuracy ensure uncompromising quality and optimum service.

(September 2013)