Long-Standing Collaboration Spanning All Generations of NUM Systems

Entering Meccanica Ponte Chiese is like entering a museum dedicated to NUM. The first numerical control system is around thirty years old, while the most recent belongs to the latest generation. Allowing you to see and feel the technological evolution not only in the field of numerical control, but also in its direct application in the production environment. The partnership between NUM and Meccanica Ponte Chiese is a long-standing one, which has been consolidated over time. For example, consider the case of a recent important investment made by the company to replace the CNC Fanuc 31i CNC system in a legacy MCM machine with a Flexium+ 68 from NUM.

Let’s start from the beginning.

Meccanica Ponte Chiese was founded in 1973 by Giovanni Ferraboli, but it was in 1978 that it took the name it still bears today. Headquartered in Prevalle, within the province of Brescia, the company specializes in contract machining for a wide range of sectors: agriculture, earthmoving, wind power, shipbuilding, textiles, energy and so on. The founder Giovanni Ferraboli is still at the helm and has been supported for years by his children Gianluca, Mirko and Monica. The company’s production facility covers an area of 10 thousand square meters, of which more than 6 thousand are covered, and houses eleven MCM machining centers. All equipped with NUM numerical control, and a metrology room with three quality control machines, responsible for checking and certifying every piece produced by Meccanica Ponte Chiese before delivery.

The machine centers at Meccanica Ponte Chiese’s plant operate 24 hours a day, 7 days a week all networked and managed by a central system aimed at optimizing production precesses. “The first MCM machining center installed in 1988 was already equipped with NUM numerical controls, specifically a NUM 560”, explains Gianluca Ferraboli, who is now head of the production department. “In 1994, we bought the second machining center, also MCM and again equipped with NUM CNCs, but in this case with a NUM 760. Then, every two or three years, we would make further investments to complete the existing equipment or introduce new ones, and thus be able to respond to market requirements in the best possible way. At the Meccanica Ponte Chiese facility, we started with the first two generations of NUM’s analogue systems - the 760 CNCs, followed by the 1060s - and then moved on to digital systems - first the 1050s, then the Axiums and finally the Flexiums.” The well-thought-out strategy pursued by Meccanica Ponte Chiese and based on the decision to implement only MCM machines equipped with NUM numerical control in its plant stems from very specific requirements.

“First of all”, explains Gianluca Ferraboli, “the simplicity of programming, which - in our case - is mostly done on board the machine; by now, each of our operators is very familiar with NUM’s CNC development environment, which greatly reduces the time required for this operation. The new Flexium+ 68 release has also further improved the usability of the system through a more user-friendly interface and the overall versatility of the system.”

Another key aspect is the ability that NUM CNCs offer to maintain part program compatibility over the years across all installed controls. “Over the course of our history”, continues Ferraboli, “we have built up a library of machining programs that are still used today because they contain all of Meccanica Ponte Chiese’s know-how. It goes without saying that it is essential for us to be able to load these programs onto all our machines, including those equipped with the latest generation systems, so that they can be used without having to redo them from scratch every time.”

Last but not least, the after-sales service is also important. “The relationship between NUM and Meccanica Ponte Chiese is a long-standing one, based on openness and collaboration”, Ferraboli points out. “In today’s market, characterized by increasingly hectic delivery times and almost cut-throat competition, machine downtime is hard to tolerate. That’s why it’s so important for us to be able to pick up the phone and find a skilled technician on the other end who can solve the problem quickly. And NUM is able to offer us just that.”

All of these reasons led Meccanica Ponte Chiese to make a very specific choice. In 2018, it decided to purchase a used Tank 1300 MCM machining center equipped with a Fanuc 31i CNC.

“Some time ago”, says Ferraboli again, “we found ourselves having to manage a strong peak of work in conjunction with which we had the opportunity to purchase a Tank 1300 horizontal machining center, 4 axes, 10 pallets and a 400-tool magazine. From the very first months of use, however, we realized that the machine’s CNC required much longer programming times, as it did not provide us with many of the functions we were used to using with NUM controls and, above all, did not allow us to load our library of programs into the machine. Not to mention the operational difficulties for our technicians.”

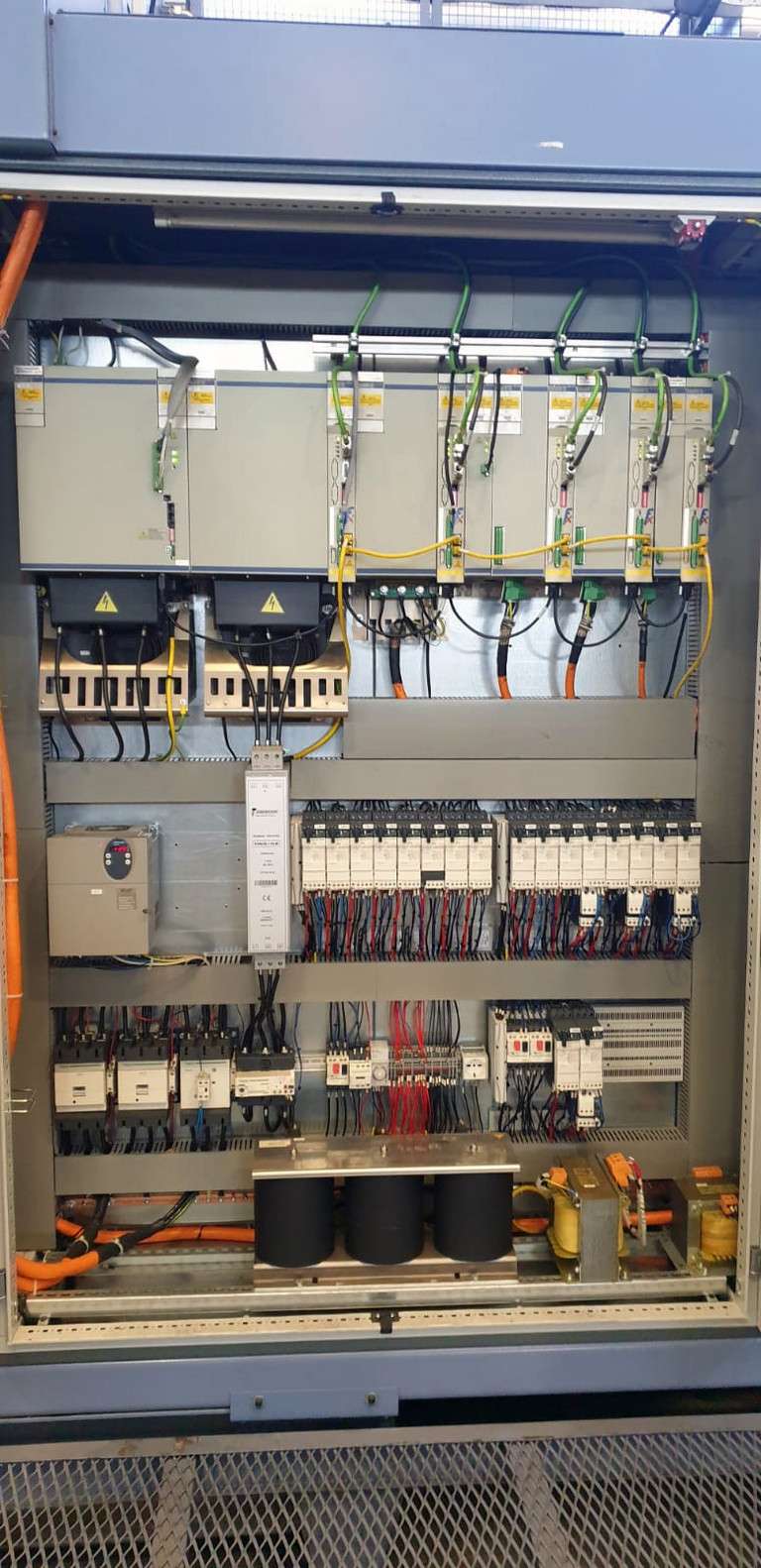

And so, Meccanica Ponte Chiese decided to make a major investment to replace the CNC and equip this machine with a Flexium 68+ CNC, MDLUX drives and BPH series motors.

(September 2021)