Strausak – the flexible U-Grind pays homage to the company’s tradition

Strausak has made an impressive comeback to the market with the flexible U-Grind grinding machine, which has allowed the company to perpetuate the good reputation enjoyed by its predecessor model, the Fleximat. Strausak also shares a long tradition of cooperation with NUM. The U-Grind, like the Fleximat before it, comes with a NUM CNC system and the NUMROTOplus tool grinding software package.

Strausak, which was founded as a repair workshop for the local watchmaking industry in 1923, is a typical Swiss company that specialises in the development and construction of machine tools to meet exacting demands in terms of technology and quality. The company sought to diversify at an early stage in order to distance itself from the fluctuating economic cycles of the watchmaking industry.

For Strausak, the development and construction of curved milling and grinding machines not only represented a successful diversification, it also constituted a foothold in future-oriented CNC technology. In the 1980s, a number of new specialist machines for precision milling and grinding of complex components for the textile, turntable and computer industries were produced. A close, successful cooperation between Strausak and NUM on CNC systems and programming has also existed since that time. In the early 1990s, Strausak AG developed a new tool grinding centre with five controlled axes – the Fleximat was born. It brought high levels of flexibility and productivity to many machine tool operators in terms of grinding tools of all kinds.

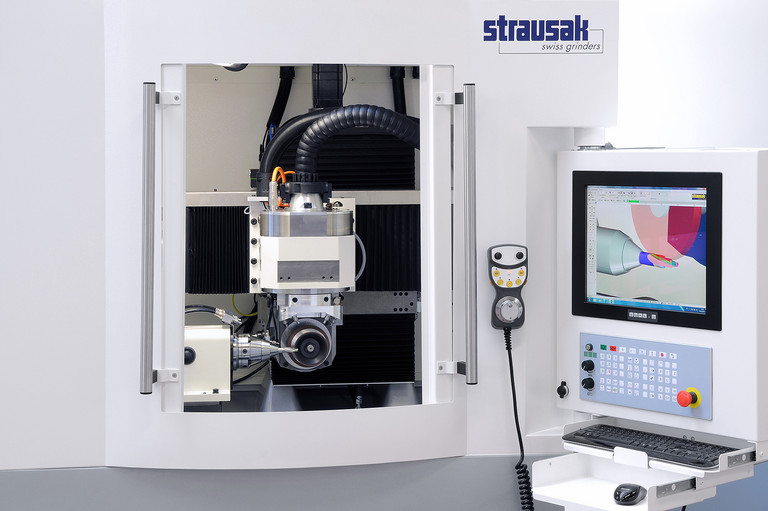

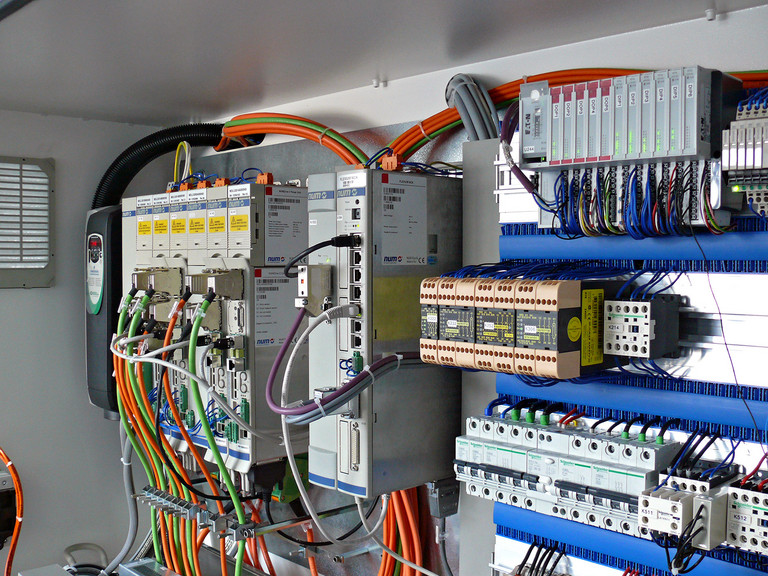

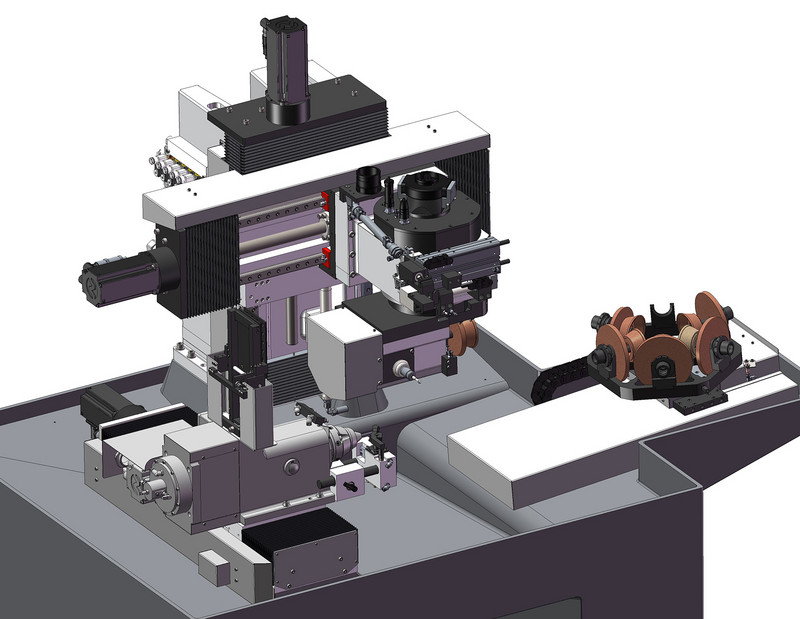

In 2012, Strausak AG, now part of Rollomatic Holding SA, launched the U-Grind, a new tool grinding centre with a latest-generation Flexium CNC system and the NUMROTOplus software package. For Strausak and for NUM, high levels of precision and quality have always been and will continue to be the most important objectives when it comes to the design of CNC machines as well as CNC systems and software.

What sets the U-Grind apart is that it is hugely flexible and economical to run. The quick and easy set-up and conversion processes result in extremely economical production times. The U-Grind is suitable for sharpeners and also for the production of high-precision small series. All five axes are powered directly to guarantee the ultimate in precision. The motor spindle for the B axis outputs 12 kW and produces speeds of 500 to 12,000 rpm. The high levels of rigidity and quiet running are due to the cast-iron base of the CNC machine and good insulation. This rigidity guarantees excellent surface qualities and tight measurement tolerances. The resting surface has been considerably reduced, a move that is also welcomed by the users. The machine is fitted with a 6-way disc changer that can be loaded from the outside. The U-Grind can be opened from three sides to facilitate set-up and maintenance.

Over the last few years, Strausak has undergone a process of reorganisation, and the 9 employees at the 1700 m2 company site in Lohn-Ammannsegg can now produce up to 10 CNC machines at the same time. The U-Grind will be exhibited on Strausak’s 60 m2 stand at the EMO Hannover 2013 trade fair. The functions of the NUMROTOplus software package, which controls the movements of the U-Grind by means of the NUM Flexium CNC system, will also be explained to all interested visitors.

The combination of a robust, precise machine and a high-performance CNC system with strong, flexible software has allowed Strausak to closely associate the U-Grind with its highly successful predecessor model, the Fleximat.

(September 2013)