Lih-Jaan and NUM: Accelerating Innovation in Worm Thread Grinding

Since its founding in 1984, Lih-Jaan has earned a strong reputation for precision engineering, particularly in the field of thread and cylindrical grinding machines. With decades of experience and a commitment to quality, the company became a trusted name in its industry. But as manufacturing demands evolved and the complexity of applications increased, Lih-Jaan set its sights on a new challenge: worm thread grinding. This highly specialized process requires not only technical precision but also a deep understanding of machine control and customization. To take this next step, Lih-Jaan needed a partner with the expertise and flexibility to support such an ambitious move. That’s when they turned to NUM - a company known for its advanced CNC solutions and collaborative approach to innovation.

Visit Website

Visit Website

A New Challenge: Worm Thread Grinding

For over 40 years, Taiwan-based Lih-Jaan has been known for building solid, reliable grinding machines – especially for thread and cylindrical applications. Their reputation for precision and consistency has made them a go-to partner across a wide range of industries. But as customer demands began shifting toward more specialized and complex parts, one request kept coming up: worm thread grinding.

It was a challenge the Lih-Jaan team was eager to take on – but one that required going beyond their existing capabilities. Worm thread grinding is a niche process with tight tolerances and high complexity. The market was small but growing, and customers wanted machines that could handle low-volume, high-mix production without compromising on precision. Lih-Jaan had the experience and ambition. What they needed was a control solution – and a partner that could move fast. That’s where NUM came in.

Laying the Groundwork for Innovation

The partnership between NUM and Lih-Jaan demonstrates the power of long-term cooperation based on mutual respect and shared vision. What began as an initial conversation around the NUMgrind software platform evolved into a strategic alliance driven by innovation and opportunity. A renewed momentum emerged when Lih-Jaan identified a specific market need, leading to a strengthened cooperation between the two companies. Working hand in hand, they developed a customized solution that combines flexibility, user-friendliness, and the ability to support a wide range of worm thread profiles. Despite a few time-related challenges in the final stages, the joint efforts culminated in a successful machine delivery—perfectly timed for its debut at TIMTOS 2025.

One Machine, Full Functionality

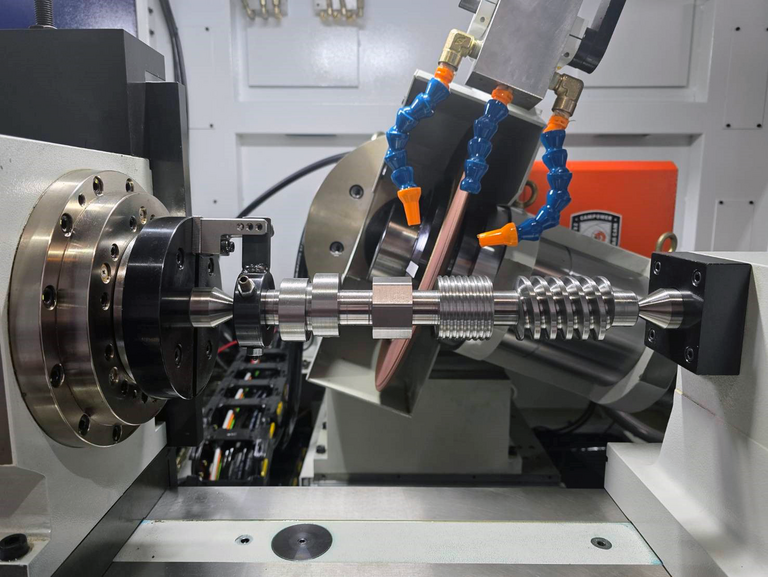

The result was a newly developed worm thread grinding machine. At its core: NUM’s Flexium+ 68 CNC system, paired with a version of NUMgrind and worm thread grinding HMI and MDLUX axes. But it wasn’t just the hardware that made the difference-it was how the system was engineered to work seamlessly with Lih-Jaan’s machine concept.

The machine supports five different types of worm threads, including multi-start threads, and allows for both cylindrical and non-circular grinding-all in one setup. Key features include:

- A user-friendly, application-specific HMI with no programming required

- A custom teach-in interface that simplifies grinding wheel setup

- Achieved roundness accuracy of 2µm

- Optional multitasking: cylindrical and worm grinding on the same machine

“NUM’s total solution not only expanded our product portfolio, but also enabled us to realize our goal of developing a specialized multi-tasking machine. In the past, customers needed two separate machines for thread grinding and cylindrical grinding. Now, they can access all functions – including worm thread grinding – in a single, integrated solution,” says Ava Tsai, Sales Manager at Lih-Jaan.

Built in a Month - Ready for the Show

Deadlines don’t get tighter than this: full commissioning – including sample parts for display – was delivered by NUM within a month. Just in time for TIMTOS 2025.

“This kind of execution is rare,” Tsai says. “NUM’s engineers were proactive, technically strong, and highly responsive. They didn’t just support us – they worked like part of our team. They even coordinated with third-party vendors to keep everything on track.”

More Than a Vendor - A True Partner

In the end, the success of the project wasn’t just about delivering a new machine. It was about building a new capability – and a new kind of relationship.

“We are dedicated to fulfilling customer requirements without compromise.” says Johnny Wu, General Manager at NUM Taiwan. “Based on this principle, we don’t just stick to what’s within our direct responsibilities – we go beyond by proactively engaging with other suppliers, taking the initiative to align on weekly targets, and actively following up on key project milestones.”

Looking ahead, Lih-Jaan sees this project as a blueprint for future innovation. With NUM as a technology partner, the company is ready to take on whatever challenges come next.

(August 2025)