NUM and Agile Wing: A Precision Partnership Shaping the Future of Multi-Functional Grinding

In Taichung City, Taiwan, where high-tech manufacturing pulses at the heart of industry, Agile Wing is quietly transforming the landscape of grinding machine technology. Though founded just in 2019, this forward-thinking company has carved out a reputation for designing special-purpose grinders that don’t just meet expectations—they redefine them. But innovation rarely happens in isolation.

When Agile Wing set out to develop a new generation of multi-tasking cylindrical grinders, they already had a powerful ally in mind. Through their sister company, Speed Tiger, they had long been familiar with NUM’s CNC systems and solutions. Speed Tiger had relied on NUM’s technology for years, particularly in tool grinding applications. So when Agile Wing faced the challenge of creating a more advanced, more intuitive cylindrical grinder, the decision to partner with NUM felt less like a leap and more like a natural next step.

Challenge: The Uncomplicated Complexity

Cylindrical grinding may sound simple, but the demands of modern production are quite different. Agile Wing needed a machine capable of performing high-precision thread grinding, external cylindrical grinding, and non-circular profile grinding – all within a compact footprint. At the same time, operators required an intuitive and flexible human-machine interface to avoid laborious programming. This combination of complexity and usability is where many systems fall short. But not NUM. After multiple technical discussions and product demonstrations, Agile Wing made their decision: they would rely on NUM’s solution for all future external cylindrical grinding operations.

The Solution: NUMgrind and Flexium+ 68—Tailored to Fit

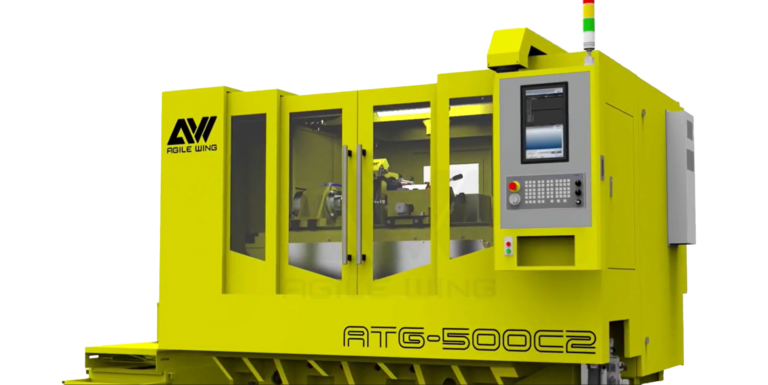

The machine at the center of this collaboration is no ordinary grinder. It’s a multi-tasking powerhouse, integrating cylindrical, non-circular, and thread grinding functions in a single unit. Powered by NUM’s Flexium+ 68 CNC system with seven MDLUX axes and NUMgrind software, the machine offers a level of flexibility that’s hard to match.

The star of the show, though, is the custom HMI developed. “NUM’s total solution not only increased our product range,” says Agile Wing General Manager Mr. Chen, “but it also achieved our goal of creating a specialized multi-tasking machine. In the past, customers needed two machines – one for thread grinding and another for cylindrical grinding. Now, they get everything in one.”

The integration of a grinding wheel magazine and automatic tool changer turned this already powerful machine into a 24/7 production solution. The HMI was even customized to support Agile Wing’s unique dual-spindle configuration, letting users choose the spindle directly via the interface – no coding required. This is especially valuable in small-batch, high-mix manufacturing environments, where flexibility and fast changeover are essential.

Race Against the Clock: From Commissioning to Exhibition

Time was a critical factor. One of Agile Wing’s first machines using NUM’s system was slated for the CIMT exhibition in Beijing, one of Asia’s largest showcases of industrial machinery. That meant tight deadlines for design, commissioning, and logistics.

“One of the biggest challenges was the limited time for commissioning,” recalls Mr. Chen. “But NUM’s engineers provided almost perfect procedures to support us. In the end, we completed all the tasks and shipped the machine successfully.”

This smooth implementation was no accident. It reflected NUM’s hands-on, partnership-oriented approach, combining Swiss precision with global agility.

Benefits That Go Beyond Technology

It wasn’t just about hardware and software. It was about vision. “NUM’s system has already integrated and optimized the grinding process functions, which is a very effective approach,” says Mr. Chen. “It not only shortens the machine development timeline but also lowers the learning curve for operators.”

This collaboration isn’t simply a supplier-customer relationship – it’s a platform for co-innovation. Agile Wing has already begun extending the capabilities of the machines they develop with NUM into highly specialized sectors, for example, the semiconductor industry.

“In terms of intellectual property protection for multi-functional machine development, Agile Wing is committed to significant investment,” Mr. Chen explains. “To date, the company has obtained multiple invention patents in countries including the United States, Japan, Korea, China, Germany, Australia, and Taiwan, and has successfully applied these patented technologies to actual products.”

A Blueprint for the Future of Grinding

For Agile Wing, this partnership is just the beginning. “The foundation of our cooperation with NUM lies in its strong integration of hardware and software,” Mr. Chen says. “We promote in-depth collaboration through an innovation- and invention-driven mindset, aiming to create product differentiation. This approach reflects the future trend in the development of multi-functional machines.”

NUM’s technology – and their team – have become key enablers of Agile Wing’s growth strategy. Together, they are not just building machines. They are building a roadmap for smarter, more adaptable manufacturing. And that’s a story still being written.

(August 2025)