Where Technology Meets Precision: BAIER and NUM Shape the Future of Embossing

How does a traditional company stay at the forefront of innovation? By challenging the status quo, exploring new ground — and partnering with experts along the way. That’s exactly what BAIER has done. In collaboration with NUM, BAIER successfully brought together two worlds: traditional hot stamping technology and modern CNC control. The result is a high-precision, future-ready system for advanced functional foil bonding — a true showcase for the next generation of mechanical engineering.

Visit Website

Visit Website

The Future of Embossing Technology

For BAIER, the future is clear: greater precision, increased flexibility, and full digital integration. In a groundbreaking customer project, the long-established company took a major leap forward. Together with NUM, BAIER developed a highly sophisticated system that, for the first time, merges CNC control with embossing technology into one platform. The outcome? A high-performance solution for advanced functional foil bonding (FFB) developed for Leonhard KURZ Stiftung & Co. KG, setting a new benchmark for the industry.

Technology You Can See — but Not Feel

Modern user interfaces are about more than just looks. Whether it’s the dashboard of an electric vehicle or the control panel of a washing machine, touch displays must not only be intuitive – they must be flawlessly finished. That’s where FFB technology comes in: combining functional films with technical components requires an extraordinary level of precision and cleanliness – comparable to the standards of medical technology.

When tasked with developing a new FFB system for a leading heat pump manufacturer, BAIER quickly realized that the complexity of a four-axis system had outgrown the capabilities of conventional controls. What was needed was a powerful CNC solution – a first for BAIER.

Two Specialists, One Vision

In NUM, BAIER found the ideal partner. Beyond the convenience of being nearby, NUM’s deep expertise in custom machine tool applications made the decision an easy one. NUM’s open CNC platform allows for application-specific customization all the way down to the control core – a crucial advantage for creating highly specialized machines.

Collaboration Across Disciplines, Focused on the Future

Despite decades of combined experience – NUM in CNC technology and BAIER in embossing – the project pushed both companies into new territory. Thanks to a close, interdisciplinary approach, the teams were able to execute the project with precision, structure, and flexibility.

All project requirements were jointly defined during a kickoff meeting in March 2023. Based on a comprehensive specification sheet, NUM created a functional design and took responsibility for sourcing and designing all electrical components — from CNC drives and motors to visualization systems and control panels. Meanwhile, BAIER handled the mechanical engineering and assembly.

After successful software testing, NUM’s application engineers programmed the PLC system and commissioned the controls. An intuitive HMI interface was also developed specifically for this system to ensure easy operation.

One critical success factor: the project was run with an agile approach. New requirements could be integrated at any time, and direct communication kept the process flexible and efficient.

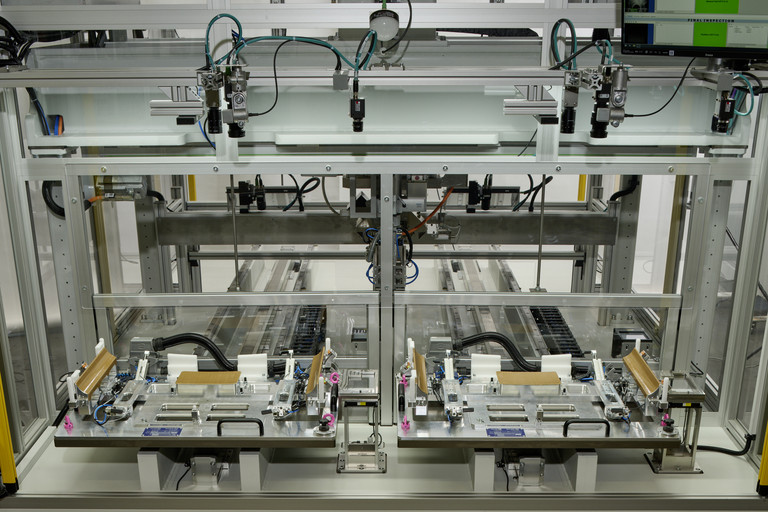

Simultaneous preparation and embossing is possible thanks to two embossing tables. The holders on the embossing tables can also be swapped so that components from the same product range can be processed in different sizes.

Built for Today – and Tomorrow

Commissioning was completed in February 2024, and final acceptance testing by the end customer wrapped up successfully in June. The system was fully delivered and integrated at the customer’s site by November. Today, it’s proving itself with outstanding performance: it’s stable, user-friendly, and low maintenance. Minor system adjustments have been handled independently by the customer, thanks to targeted training provided by NUM and ongoing support from BAIER.

For BAIER, this project marked more than just a milestone – it opened the door to new opportunities. A second, identical machine is already in planning, and additional CNC-driven projects are on the horizon, including ventures into new areas like digital printing.

A Partnership with a Future

“This was real teamwork – collaborative, solution-oriented, and efficient,” says Thea Huttenlauch, Managing Director at BAIER. Marc Riedl, Area Sales Manager at NUM, agrees: “Working with BAIER really showed how versatile our CNC system is. We’re excited for many more joint projects to come.”

What remains is a powerful message: when experience meets innovation, the technologies of the future are born.

(August 2025)