Technological Collaboration Serving the Railway Sector – Handling, Welding, and Grinding of Tracks

Building a fully automated 200-meter-long rail part welding facility is no easy feat, and the companies capable of achieving this can be counted on one hand worldwide. Piacenza-based Provide Solution is one of them, thanks in part to the invaluable support offered by NUM, which, in addition to supplying the numerical control, has developed ad hoc software for this application.

Visit Website

Visit Website

For subsidiaries Provide Solution srl and Labormak srl, which specialize in the design and implementation of automation solutions for a wide variety of application areas, nothing is standard.

“Since our companies are completely devoted to the needs of the customer,” explains Labormak Production Manager Andrea Montanari, in fact, “every job order we take on is a real challenge, since it means having to make something that basically does not yet exist and therefore has to be studied, designed and implemented from scratch.”

Founded in 2011 thanks to a long experience in the machine tool sector, Provide Solution is now a highly specialized mechanical, electrical and software design center with a staff of 40 people and a turnover of 3.5 million euros. Labormak – with 25 employees and a turnover of 2.5 million euros – handles the implementation and testing for most of the systems developed. Watchword: automation. Regardless of the product sector and, when necessary, with the technological support of high-level partners.

One such partner is NUM, with whom Provide Solution has been collaborating for more than ten years. It all began about four years ago, when Elettri-Fer srl and S.i.c.e. srl v formed in temporary consortium – turned to Provide Solution after winning a tender called by RFI – Rete Ferroviaria Italiana for the construction of a rail welding and finishing plant.

A very complex process that, of course, involves numerous steps, as Andrea Montanari explains “Inside a loading warehouse, pieces of rail to be welded are introduced,” he recounts, “which are then moved from one processing phase to another by means of conveyor rollers. In particular, they have to go through brushing, since the ends of each piece have to be cleaned before they can be welded; marking, so that individual pieces can also be identified later and outside the line; and then to the most important and delicate stage, which is the actual welding.”

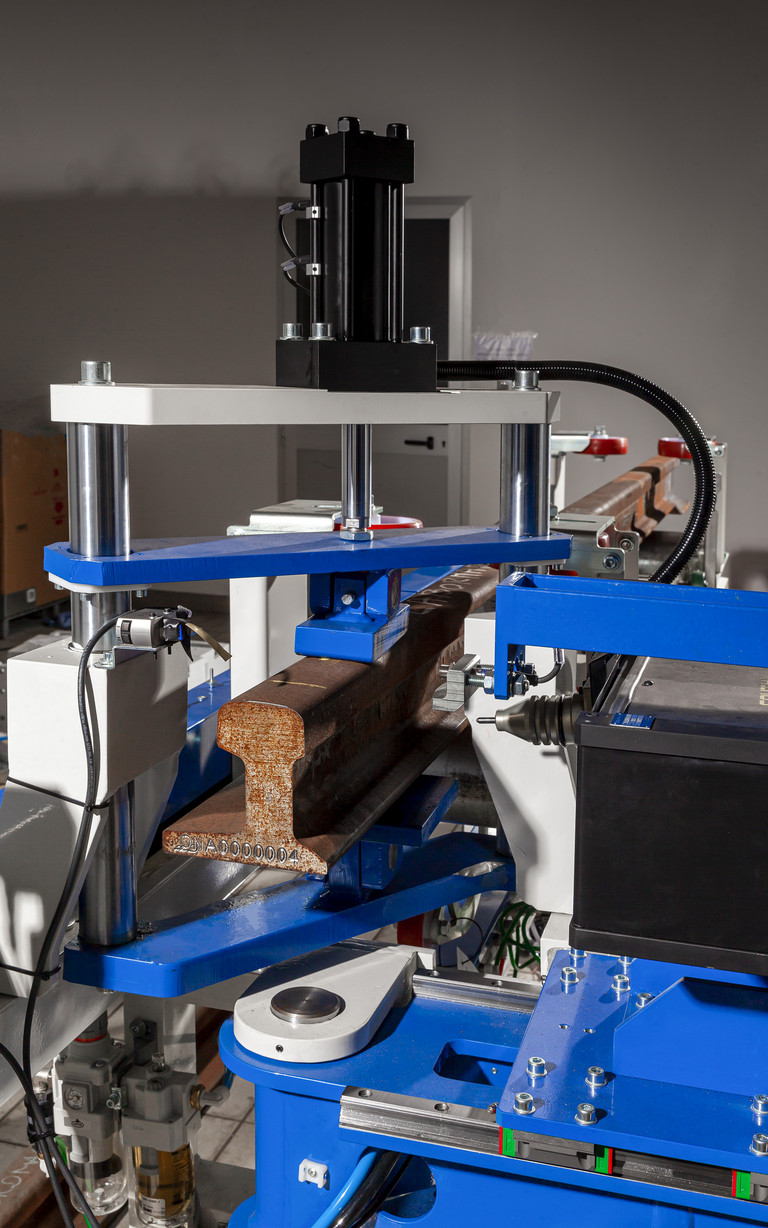

This is followed by cooling, straightening (to remove the deformation caused by the welding), and, finally, the grinding process, which is necessary to eliminate – for safety purposes – even the smallest imperfections. Companies capable of developing such complex plants are few, and Provide Solution is one of them.

Part of the design complexity undoubtedly stemmed from the size of the line, which spans 200 meters and thus would necessarily have had to be partly outdoors.

Moreover, Provide Solution had to invent a line that would automate a number of operations that had previously been done manually by the operator (such as grinding). Today, there is no human intervention on the line except for the loading and unloading of parts.

“It has happened to us several times in the past to integrate units external to our implementation,” Montanari adds. “In this case, however, we are talking about a line made up of several machines, most of them not produced by us, which had to be not only integrated but also customized so that operations could take place fully automatically.”

The automation of the entire system therefore came entirely from Provide Solution, as did the brushing machine, the marking device, and the machine in charge of removing residual welding (before) and grinding (after). The latter with the help of NUM.

“It was immediately clear to us that, to handle such a complex machine,” Montanari continues, “a high-level numerical control would be needed. Since this is a prototype machine, moreover, the decision to involve a technology partner with whom we have been collaborating for years, such as NUM, was also dictated by the fact that, at the outset, we were not perfectly clear on the steps that would lead to the achievement of the final objective and, as a result, it was necessary to analyze every single machining operation.” Dealing with a special machine, it was necessary to implement a very flexible CNC that would allow different types of customizations and thus be optimally suited to the needs of this specific application case.

“The system we implemented,” points out Marco Battistotti, NUM’s NTC Italy Director, “is a Flexium+ 68, complete with digital drives from the MDLUX range, brushless motors in the single cable version and equipped with absolute encoders.”

Andrea Montanari then highlights another very important aspect. “On the market,” he goes on to explain, “there are no machines for grinding pieces of rail capable of machining it along the entire section profile in a single fully automated process. So much so that for this purpose we had to design and develop an ad hoc one that was able to customize cycles, since when the rail pieces reach the grinding stage they are different from each other. This means that there is no single program that is good for all machining operations, but it requires the intervention of software based on parametric algorithms that, depending on the measurements that are taken, automatically makes the appropriate corrections.”

Provide Solution has thus implemented a data acquisition process, depending on which the rail piece will then be machined correctly.

(August 2025)