Collaboration speeds development of glass screen finishing machines

Customized CNC systems and in-depth engineering support from NUM are enabling specialist machine manufacturer Viewtrun Technology to enter and compete in fast-growing markets in Asia.

Based in Taipei, Viewtrun is developing a range of glass finishing machines for consumer electronics products that set new cost/performance levels in this highly competitive automation sector. This market is currently dominated by high-end machines produced by Japanese manufacturers.

Viewtrun has chosen to base all its machines on CNC systems from NUM primarily because it wanted to partner with a CNC company prepared to collaborate on the development of custom hardware and software to shorten its time to market and add value. Another key factor was that the CNC system itself needed to have an open architecture, to provide a flexible platform for future machine development.

According to Adrian Kiener, Managing Director of NUM Taiwan, "The market for glass finishing machines is relatively young, so Viewtrun didn't want to get locked into proprietary control technology that might preclude taking a particular design route sometime in the future."

Viewtrun's first machine, the JG-500 precision glass grinder, has just been launched and is proving extremely popular. The machine is designed for manufacturers of flat panel glass-fronted displays for products such as smartphones, tablets and other touch-screen devices. It automates edge grinding of a glass panel after it has been cut to size, to remove the small chips that are an inevitable result of the cutting process. Close working tolerances are involved, to ensure the panel retains its form factor after its edges have been smoothed.

The JG-500 is a 4-axis machine with a double spindle. There are two linear axes - X and Z - and a spindle motor mounted on the vertical Y axis. All four motion axes employ NUM servomotors driven by MDLU digital servo drives, which together with the spindle motor are controlled by a NUM high-end CNC system. High speed interpolation techniques ensure tight, cost-effective positional control of motion.

A custom HMI, which utilizes special functions and parameters, and employs the Chinese language for all operator communication, was specially developed for the JG-500 by NUM Taiwan. The HMI links to a parts database that was also created by NUM specifically for the machine. NUM's ability to provide this level of local development support was another factor behind Viewtrun's choice of CNC solutions provider; it judged that it would obtain more responsive service from a company that operated in the same country.

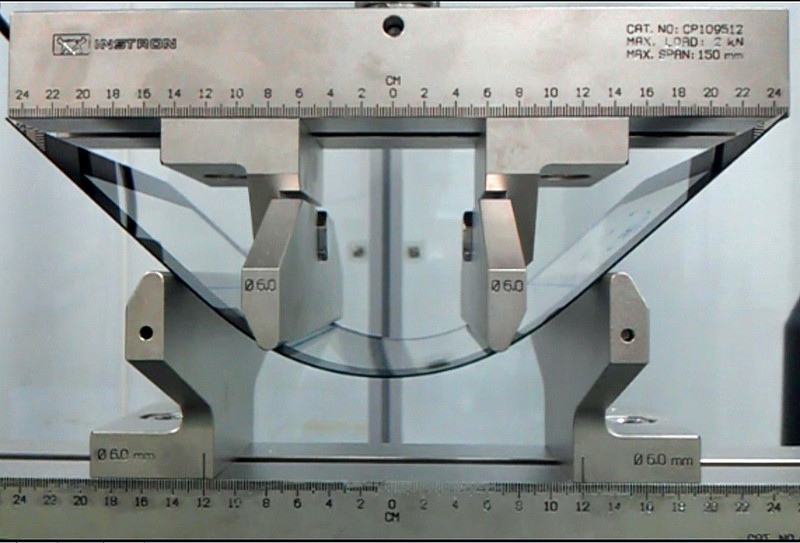

Depending on the dimensions of the glass panels being processed, the JG-500 is capable of grinding up to three times faster and more accurately than similar machines from competitors. The panels then undergo a separate finishing stage, where their edges are polished to alleviate stresses that build up in the glass during the cutting process.

To help manufacturers further simplify their production process and minimize scrap, Viewtrun has also developed a second machine that combines glass panel grinding with edge polishing. The new JP-6MA machine has six motion axes and two spindles, again all controlled by a NUM high-end CNC system, and is capable of edge polishing to an accuracy of a few microns. Panels polished to this level of accuracy have an exceptional bend strength which significantly reduces the risk of them breaking during use - a major competitive advantage in consumer electronics markets. The JP-6MA is currently sold to specific customers in Taiwan.

Joshua Kong, CEO of Viewtrun Technology, points out that NUM's collaboration is a key factor in the successful development of its new machines: "NUM's expertise and willingness to invest engineering resources in this project is enabling us to bring products to market very quickly and efficiently."

Adrian Kiener adds, "A partnership ethos has always been at the heart of NUM's business philosophy. This is proving particularly advantageous in Asia where NUM's willingness to share the risk that young OEMs face when developing new machine tools is winning us significant new customers such as Viewtrun."