Local CNC experts help Chinese company to develop radically improved gear cutting machine

combining local expertise with NUM’s unique know-how in gear production helps achieve a machine that can outpace other gear hobbers.

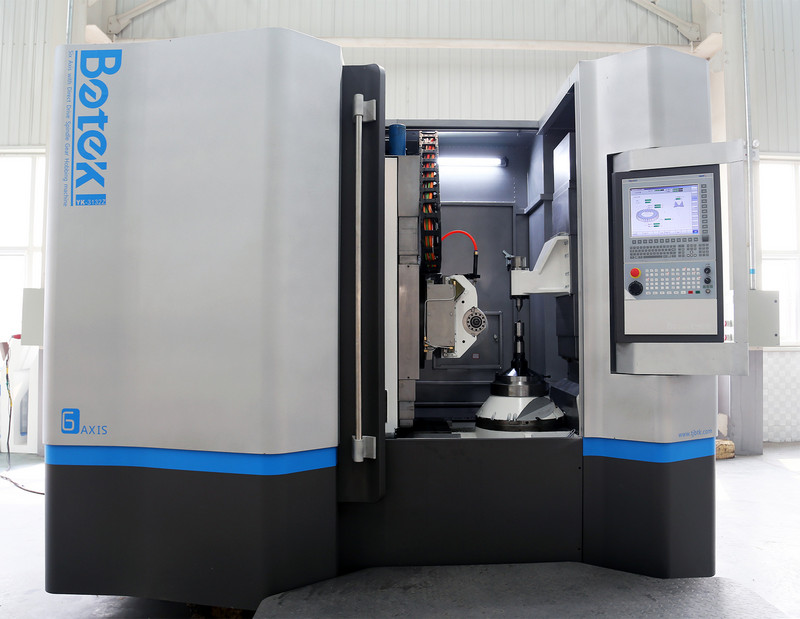

NUM China has helped Betek to accelerate the development of a groundbreaking six-axis precision gear hobbing machine. By utilising a direct-drive spindle and NUM’s ultra-precise electronic gearbox and renowned CNC gear hobbing technology, together with a unique HMI developed by a local specialist machine designer, the new Betek YK3132Z gear hobber provides unprecedented cutting speed and processing efficiency. It is up to 10 times faster than conventional mechanical gear hobbers – and more than twice as fast as competitive six-axis CNC gear hobbing machines – and looks set to establish a new performance standard for gear production automation.

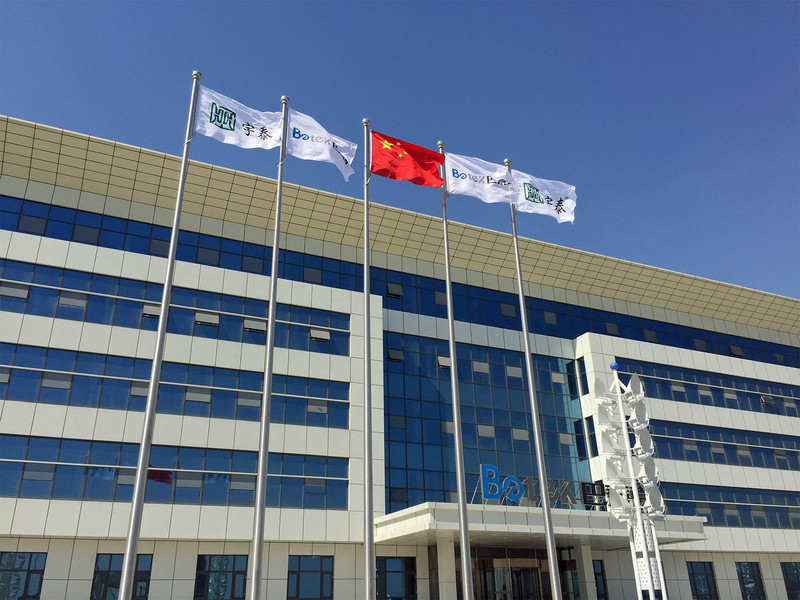

Based in Tianjin, China, Tianjin Betek Machinery Manufacturing Co., Ltd (Betek) specialises in the production and processing of mechanical parts for industrial applications. The company’s experience of using machine tools in its manufacturing operations, combined with market research, highlighted major opportunities in the domestic gear production market. China has a growing need for CNC gear cutting machines that combine precision, high processing efficiency and ease of use, to replace inefficient mechanical designs. In 2013, the company took the strategic decision to diversify into the production of gear cutting machines, investing 80 million yuan (approximately 13 million USD) in a 25,000 square metre purpose-built manufacturing plant and offices.

Betek’s latest CNC machine tool, the six-axis YK3132Z gear hobber, is now available – less than two years after the start of development. At the beginning of the project, the company looked at CNC systems from a number of manufacturers, and quickly decided to base the machine on NUM’s Flexium+ CNC platform.

According to Betek’s President and General Manager, Mr Jin Guolin, “Our main reason for choosing NUM’s CNC systems for our new gear hobber is that, unlike many competitive control products on the market, they have an open architecture. This provides an unrestricted foundation for development and customisation work, helping us to reduce costs and shorten time-to-market significantly. We intend standardising on NUM CNC for future machines whenever possible – for example, we are currently developing a new gear grinder that will also be based on NUM’s CNC technology.”

For the gear hobbing machine project, another factor behind Betek’s choice of CNC supplier was NUM’s extensive experience in gear production applications, which spans several decades. Its CNC gear hobbing solutions, based on NUMgear software, are used by many leading manufacturers of gear production machines. The proximity of NUM’s facility in nearby Beijing was also a consideration – it means that Betek benefits from responsive locally-placed applications support and technical service.

Betek’s new YK3132Z six axis gear hobbing machine is based entirely on NUM CNC equipment. It uses the latest Flexium+ CNC kernel and high-end NUMDrive X servo drives in conjunction with compact BHX and SHX servomotors; high resolution encoders and closed-loop control maximise accuracy of speed and position. Both the hob spindle motor – a built-in model – and the table (C axis) torque motor are powerful direct drive units that are also controlled by a NUMDrive X servo drive. These motors completely eliminate the need for mechanical power transmission components such as worm and helical bevel gears, resulting in precision, backlash-free movement.

The hob spindle can handle speeds up to 1,200 RPM, while the table can rotate at up to 280 RPM; this allows use of the latest high-speed cutting tools. Accuracy and reliability are further enhanced by the machine’s use of high rigidity servomotor-driven precision ball screws for its linear axes.

The NUMgear suite of gear production software that is being supplied includes dedicated hobbing functions and a precision electronic gearbox that allows all master axes and the turret spindle to be fully synchronised. The electronic gearbox minimises synchronisation time by predicting the acceleration rate as well as the speed of the axes.

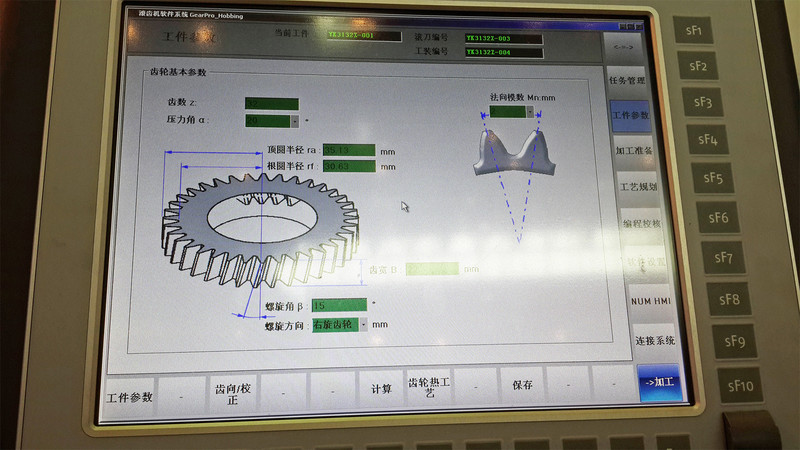

All human interaction with the gear hobbing machine is via a NUM FS152i operator panel with a custom HMI. The operator panel features a 15-inch high resolution backlit LCD screen with 22 large function keys and contains a powerful industrial PC. The HMI makes extensive use of graphics and is inherently intuitive; users can operate the machine after just a few hours of simple training. Gear manufacturing data can either be input using a simple ‘fill in the blanks’ method or derived from previously processed parts – the software includes database management functions.

The custom HMI software was developed specifically for the machine by Changzhou Mactool Precision Machine Tools Co., Ltd. This company specialises in the design of gear cutting machines and user interface software, and has invested heavily in building up the development and technical support infrastructure necessary to serve China’s nascent precision gear machine tool industry. Mactool’s owner, Mr Wang Haiyu, has more than 15 years’ experience of gear processing applications, with a particular expertise in gear hobbing and grinding machines.

Florian Schmidt, NUM’s Product Manager, points out that Mactool and NUM China have collaborated on several high value CNC machine projects in recent years, adding that: “To provide our customers with their ideal solution we combine the best of all worlds.”

Mr. Haiyu agrees on the benefits of collaboration, “I believe that partnerships provide customers with an enormous competitive advantage. By working closely together, NUM, Mactool and Betek have jointly created a highly advanced precision gear hobbing machine that looks set to enjoy significant market success. Based on a fully proven and stable CNC system, the machine is way ahead of the competition in terms of its usability, efficiency and performance. The excellent production management and quality control systems that Betek has put in place will help to ensure that its customers benefit from a world-class precision machine – but at significantly lower cost than comparable products.”

The Betek six-axis YK3132Z gear hobber accommodates gear blanks up to 320 mm (12.6 inches) in diameter. Its advanced CNC system can handle five-axis interpolation, enabling complex gear tooth profiles to be created smoothly and efficiently. The entire gear is cut as part of a single process, without interim removal/reinsertion of the gear blank or manual tool changeover.

Virtually any type of gear can be cut, including unusual types such as parallel shaft, herringbone, taper and non-circular gears. For maximum machining accuracy the machine uses dry cutting techniques, capable of achieving Level 6 precision on interim cut gears and Level 3 precision on finished products. Dry cutting also obviates the need for cutting fluid, which is a common form of pollutant in machining industries that requires special treatment and disposal.