NUMgrind - Surface Grinding Pack GS1

Shop Floor Programming Solution for Surface Grinding: NUM has extensive experience in grinding applications and is one of the world’s leading suppliers of CNC solutions for tool grinding. NUM also supports external and internal cylindrical grinding, including non-circular grinding, surface grinding as well as centerless cylindrical grinding, with CNC systems specially tailored to the respective application. Each application solution provides corresponding cycles and a matching and easy-to-use HMI.

NUMgrind for Surface Grinding (Surface Grinding Pack 1) covers all aspects of the surface cylindrical grinding process. It offers a complete “off the shelf” solution, with embedded grinding and dressing cycles governed by a user-friendly menu-driven data entry system that includes 3D simulation and wizard-guided setup. In short, NUMgrind not only saves OEMs years of development time, but also significantly reduces operators’ training time.

NUMgrind HMI Surface Grinding

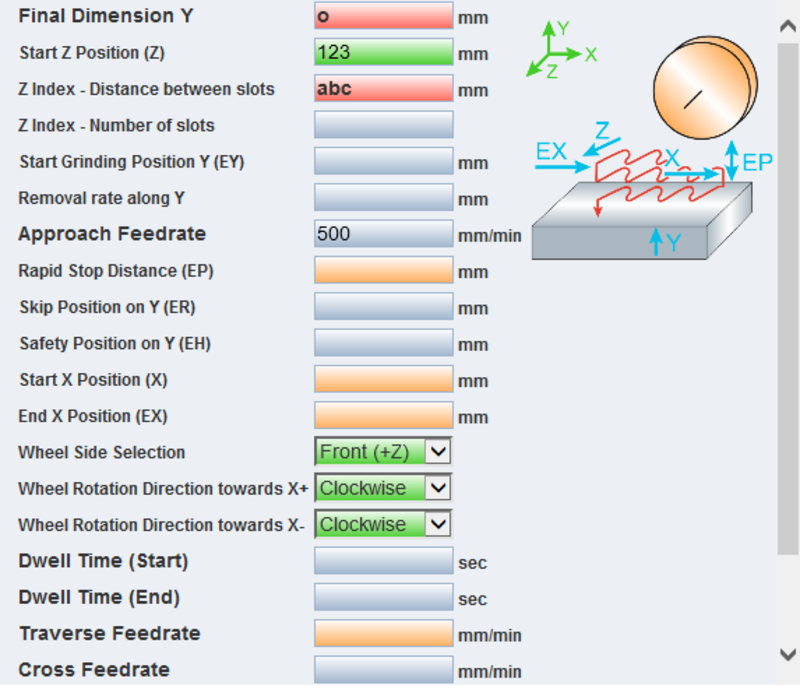

The Flexium CAM-based programming process is extremely user-friendly. Entry screens provide the machine operator with a comprehensive graphical programming approach that depicts the grinding wheel, workpiece, and associated setup data in a clear and concise manner. Operators do not have to use ISO or G-code programming; they simply fill in the data fields presented by the program. After completion of the data entry session, the grinding program is automatically generated, stored, and is then ready for execution.

The highly intuitive input fields, which support the operator with images, often also have a teach position function. This allows the operator to easily transfer the current axis position directly into the input field of the workpiece program.

This is an effective time-saving option for recording the relevant grinding positions directly on the workpiece, especially when surface grinding.

The architecture of the NUMgrind HMI is ergonomic and offers a comfortable programming experience with a very instinctive interface:

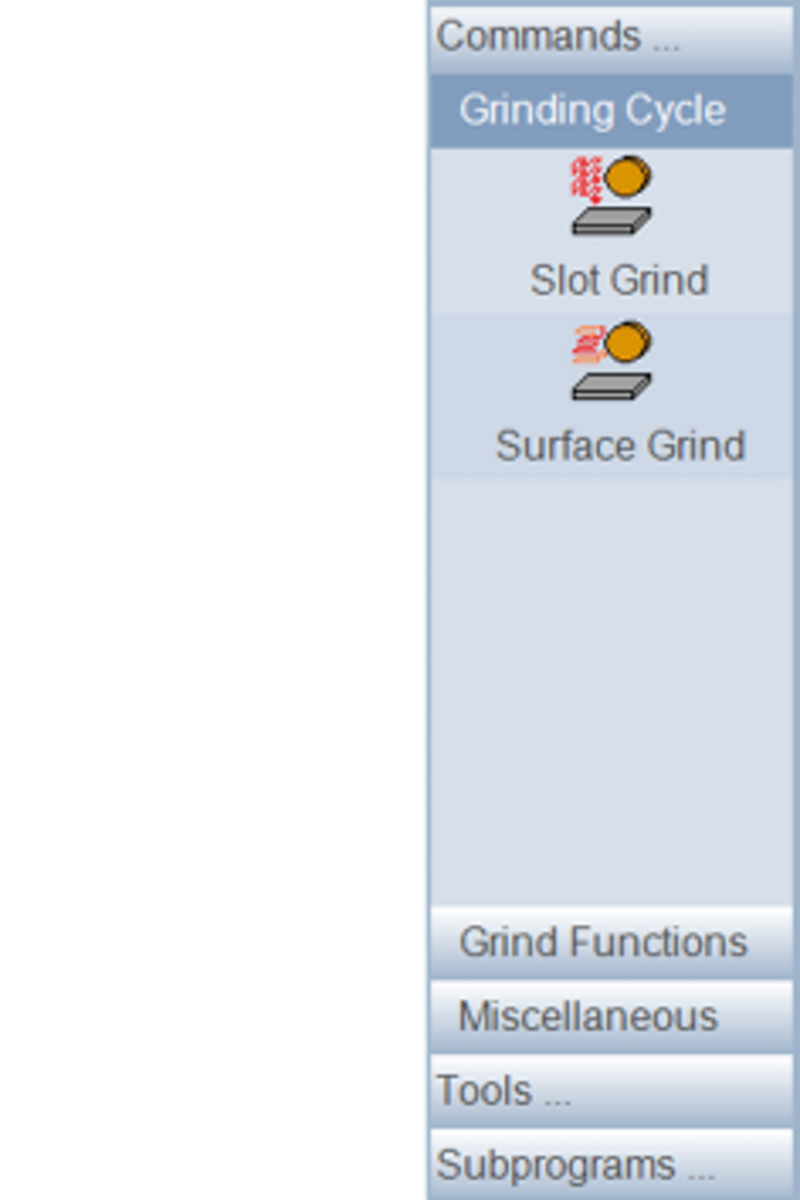

In picture 1 is the “command tree” with all available functions (general definitions, tool selection, cycles, etc.). The user interface can work with mouse, keyboard and touch screen.

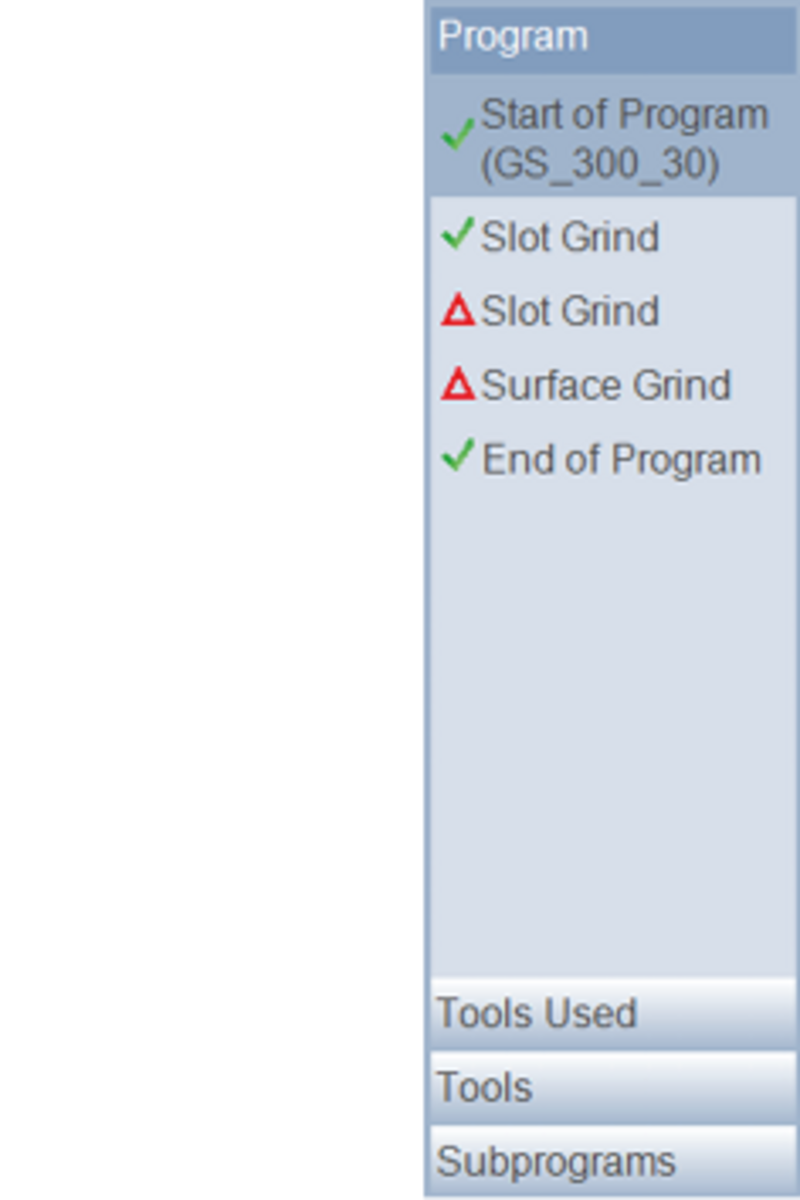

The frame 2 shows the “Program sequence”. The selected commands are inserted into it in the order that they should be performed. Whether a command is complete and plausible is indicated by a flag in green or red next to each command.

In picture 3 we have the input page with graphic support. Orange fields are mandatory fields, blue fields are optional entries. If the fields are green or red, the entry is accepted or not accepted.

The grinding cycles are designed for a 3-axis (X/Y/Z) grinding machine. The packages include the following features:

Grinding Cycles:

- Slot Grinding Cycle (with and without oscillation)

- Surface Grinding Cycle

Auxiliary Grinding Functions:

- Wheel Surface Speed Calculation

- Manual Measurement

- Emergency Retract Sequences

- Fixed 2 Diamond or Profile Dressing Roller Wheel Dressing

- Fixed 2 Diamond Dresser Wheel Shaping

- Part and Dresser Setup Routines

- Wheel Data Management (Eight Stored Setups)

- Semi-Automatic Mode (Automatic oscillation along X and if needed Z axis, manual operation on the Y axis)

Wheels:

- Straight Wheels

- Special Profile Wheels (by Profile Dressing Roller or 2 Diamond Dresser)