Advanced CNC systems help US machine tool manufacturer to extend competitive edge

Advanced CNC systems from NUM are helping US machine tool manufacturer Bourn & Koch, Inc. to extend its competitive edge in the market by using state-of-the art machine control software. Following a highly successful project to migrate control of powerful 7-axis horizontal gear hobbers to NUM’s Flexium CNC platform, the company is now standardising on this control technology for an extensive range of its gear production machines.

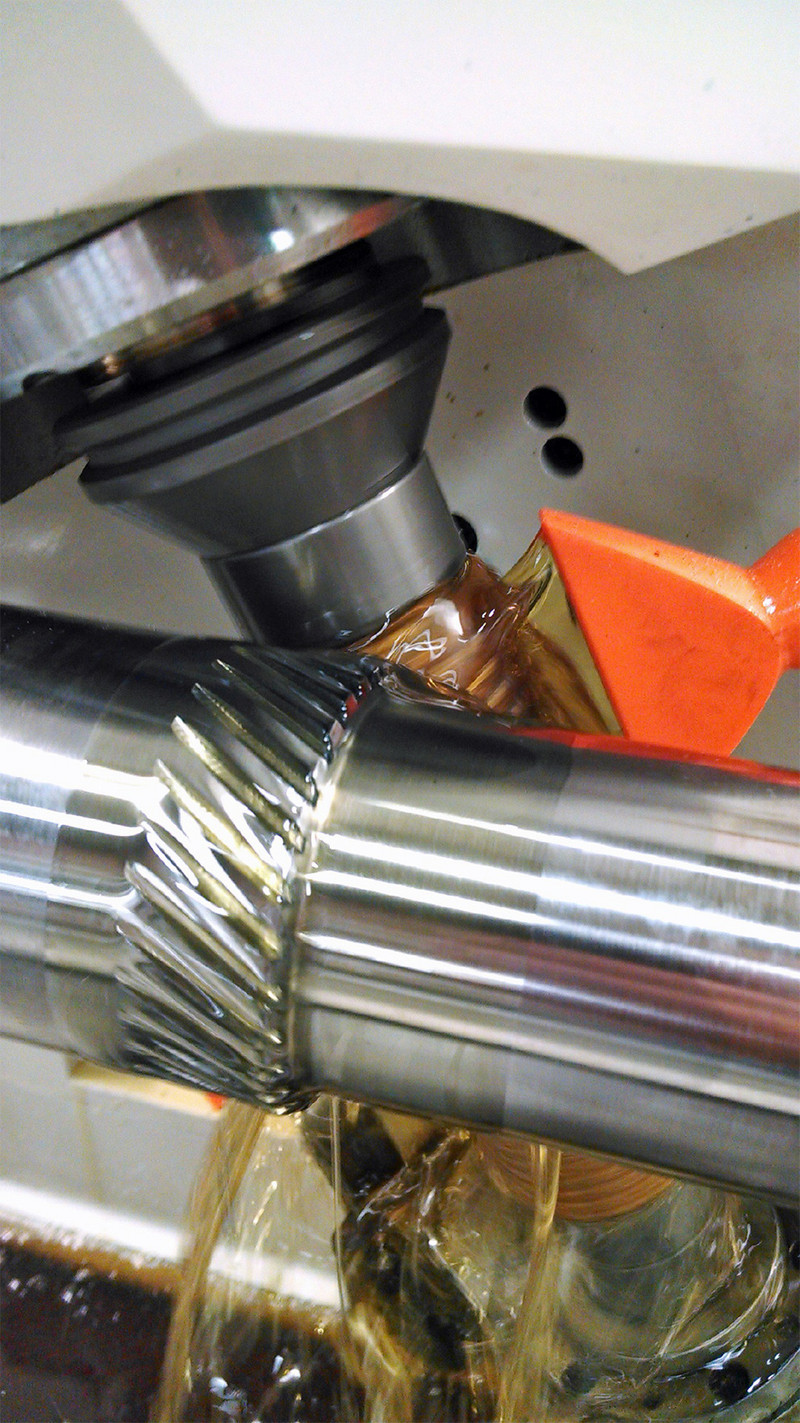

Bourn & Koch chose to upgrade to NUM’s Flexium CNC on its 25H - 400H Series II gear hobbers, starting with the 400H. The speed and power of this machine means that it can replace as many as seven older style gear production machines, making it a popular choice with companies machining large precision components such as bull and cluster gears, worms, shafts, splines and pinions. Capable of accommodating work pieces up to 400 mm (16 in) in diameter, the 400H has an axial travel capability of 1,168 mm (46 inch) as standard and can be customised for the production of even longer parts. Customers are typically prime and sub-contract manufacturers producing mechanical power transmission components and systems for the defence and aerospace, oil/gas drilling, mining, heavy equipment and power generation industries.

Bourn & Koch has partnered with NUM Corporation for over 25 years and today uses NUM’s CNC systems in many of its gear shaping, hobbing and grinding machines, as well as in various other types of metal removal machines, and for numerous CNC upgrade and machine retrofit projects. Both companies and their customers benefit from this collaboration. Jointly-developed conversational software has been cited by a number of Bourn & Koch customers as a factor in their machine purchasing decisions.

The HMI (human machine interface) on the 400H gear hobber makes full use of the software’s capabilities by combining a conversational style dialogue with powerful graphics, which means that the machine operator does not have to use or even know about ISO languages. To produce a part, the operator simply inputs machine setup information such as cutting speeds, work piece and tooling geometry via simple fill-in-the-blanks menus, while graphical images provide clear and unambiguous views of the hob tool and resultant gear part. All calculations involved in creating the machine control program for a particular part are handled completely automatically.

The company decided to migrate the design to NUM’s Flexium CNC platform as a matter of course. Tim Helle, President of Bourn & Koch, explains, “We offer customers a choice of CNC – NUM is the standard on most of our gear hobbers – and have a policy of using the latest technology to maximise the performance and cost-effectiveness of our machines. This approach also results in progressively simpler machine operation, with less need for training, and means that spares are readily available, which contributes to machine uptime and reduces customers’ support costs.”

In this instance, moving to NUM’s Flexium CNC also had technical advantages; the system’s faster block processing and loop update times offered the opportunity to reduce the machine’s cycle time and further improve its accuracy. Flexium also features more on-board NC memory, a much wider and unified set of PLC software development tools and increased freedom for OEMs to create application-specific HMIs. This additional control and HMI customisation flexibility allowed Bourn & Koch to enhance various aspects of the gear hobber’s operation.

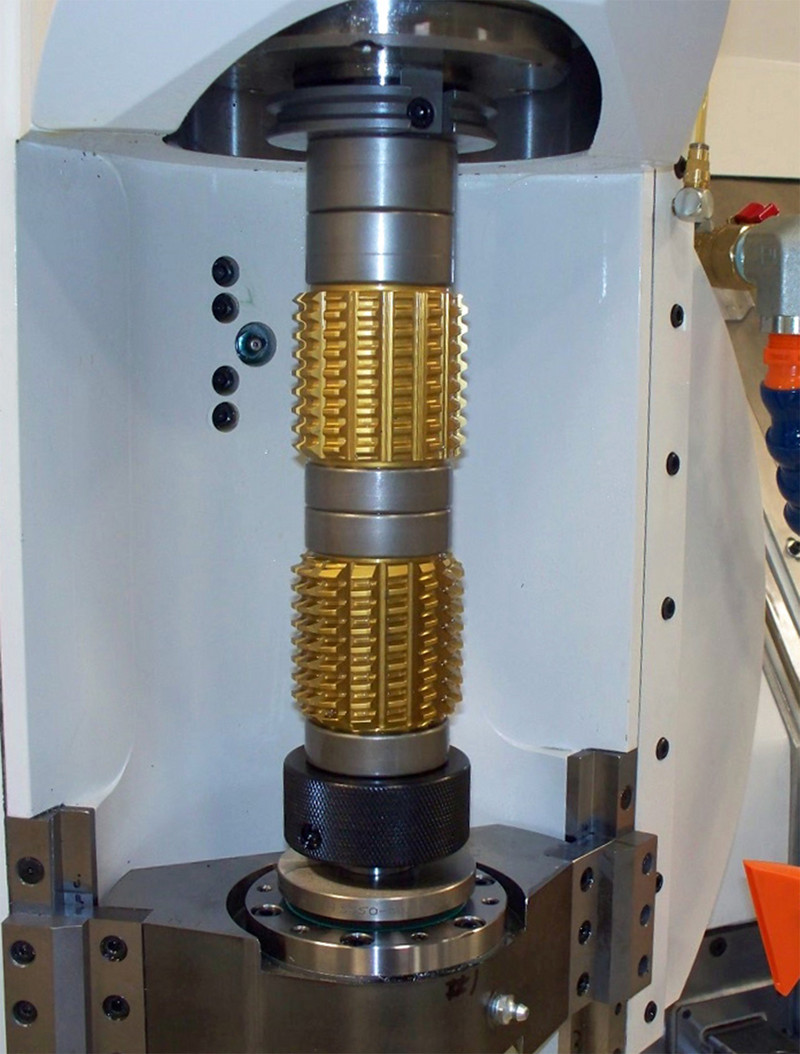

When the latest 400H Series II gear hobber is offered with NUM CNC, the entire machine is based on NUM motion control technology, with the sole exception of its (C axis) work piece spindle motor, which is a special liquid-cooled direct drive unit capable of generating 560 Nm of torque at 110 RPM. In addition to a Flexium 68 NCK (numerical control kernel) – which is the most powerful model that NUM produces and is capable of controlling up to 32 fully interpolated axes or spindles – and its associated PLC, NUM is supplying all the I/O, drives and servomotors that are used on the machine.

According to Tim Helle, “We have received technical support from NUM Corporation to assist us in making the transition from Axium to Flexium CNC systems and have already started using this CNC platform across our range of gear hobbers. Longer term, we intend offering NUM’s Flexium CNC technology on all our new gear hobbing machines.”

All seven axes of the gear hobber, including the work piece spindle motor, are controlled by the Flexium 68 CNC and NUMDrive C servo drives. The radial (X) and axial (Z) feed axes, as well as the hob head shift (Y), hob head swivel (A) and tailstock (W) axes, are all programmable and are driven by NUM BPH series medium inertia servomotors. The force applied by the tailstock servo can be changed on the fly during the machine cycle, to accommodate the changing mass of the part and prevent the introduction of any lead error. The hob cutter spindle (B axis) is driven by an asynchronous NUM AMS motor fitted with a high resolution multi-turn encoder, controlled by a NUMDrive C servodrive; a further NUMDrive C module controls the machine’s direct drive work piece spindle motor.

For simplicity and ease of operation, the 400 H gear hobber is equipped with a NUM FS152i operator panel and keyboard, mounted on the front external face of the machine with an ergonomic swing arm. The panel combines a 15-inch touch sensitive screen with an integrated industrial PC running the Windows Embedded operating system, equipped with a solid state disk and dual core processor to provide a fast and responsive HMI. A number of machine functions, such as positive/negative jog and speed override of selected axes, together with emergency stop, can also be controlled remotely using a cable-linked portable hand wheel.

The machine utilises the full four-axis electronic gearbox capability of NUM’s popular gear hobbing solution, NUMgear, to help speed production of complex gear parts. In conjunction with built-in high-speed synchronisation facilities this allows the axial and radial feeds, and the hob head shift axis, to be geared to the work piece spindle. Use of the electronic gearbox is entirely automatic; the machine operator merely needs to enter basic gear manufacturing data, such as the number of teeth, the number of tool starts, the gear module – the 400H can handle a gear module of 6.4 – and the helix angle to define and activate a specific electronic gearing function.

Particular attention has been paid to tool wear management. The software continuously monitors the condition of the hob tooling and employs a pre-programmed tangential hob shifting sequence to ensure that an efficient cutting edge is always engaged during gear generation; the entire process is automatic – it can even be invoked during a machine cycle – and the operator is prompted whenever it is time to check or replace the hob. Undamaged hobs can be reground or recoated many times before they are worn out, which helps to keep tooling cost to a minimum. Hob head synchronisation is maintained throughout the shifting process to minimise disengagement/re-engagement times and prevent tool or work piece damage.

Bourn & Koch also make use of the software’s non-contact automatic gear alignment feature to improve throughput on the 400H, by enabling a work piece that already has teeth to be automatically synchronised to the cutting threads of the hob cutter. This is mainly employed for gears that are being re-cut or for hard re-hobbing (or skiving) of helical or spur gears after heat treatment to reduce distortion errors.

As Steven Schilling, General Manager of NUM Corporation in Naperville, Illinois, points out, “Bourn & Koch is one of our most valued customers and a key business partner. It has a large installed base of customers that use machines equipped with NUM’s CNC systems, many of whom regard ease of operation as a prime machine tool differentiator. The company’s decision to adopt Flexium as the CNC platform for all its NUM-based offerings is a considerable accolade, both technically and commercially. We are now in the process of increasing the level of in-depth product training that we provide for its engineering, machine start-up and customer support teams, to help support this initiative.”