New CNC Functions – Trochoidal Milling Cycle (G725) and Engraving Cycle (G730)

As part of its most recent software revision, NUM launched a set of different Flexium+ NCK cycles. They are related to more effective and faster part processing in milling applications, and include an essential extension for industrial engraving applications using letters, numbers and special characters.

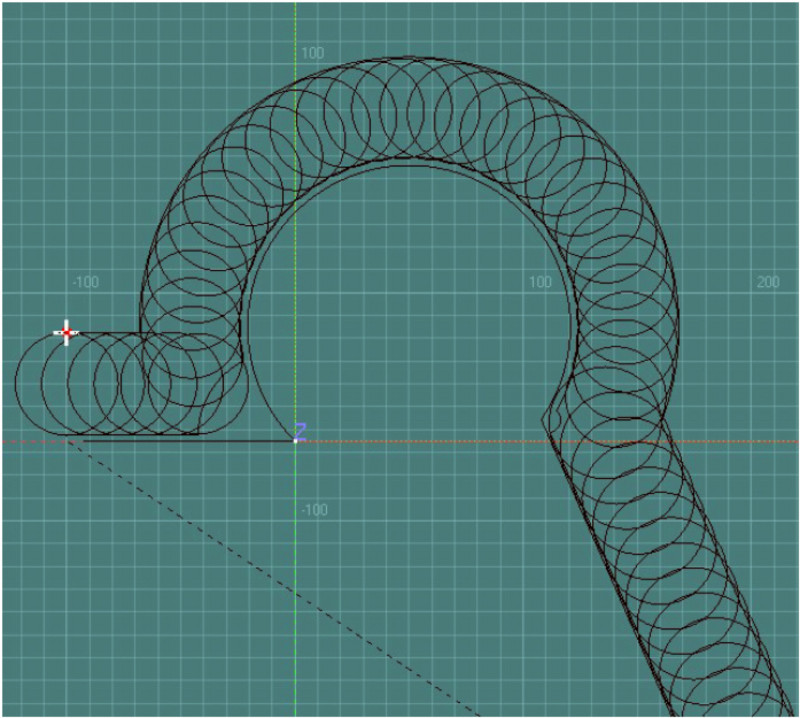

FXSO000700 Trochoidal Milling Cycle (G725)

A Trochoidal/cycloidal motion is the curve that describes a point on the circumference of a circle when the circle moves along a straight line. Trochoidal milling is a specific strategy for milling that uses new CAM programming systems and control cycles to achieve consistent tool engagement, higher material removal, and a consistent average chip thickness. As a result, optimum and effective machining processes are guaranteed.

The most important customer advantages are:

- Decreased cutting forces

- Reduced heat

- Greater machining accuracy

- Improved tool life

- Faster cycle times

- One tool for multiple slot sizes

The Trochoidal Milling Cycle can be started with G725 in NUM ISO programming with different cycle parameters, including feed definition.

The syntax is very simple:

G725 EL.. [EF.] [EG..] [ES..] [EE..] ER.. EH.. H..N.. N.. Q..

Cycle parameter description:

EL.. Width of the Trochoidal machining

EF.. Machining feed

ES.. Feed ratio for the recovery path

ER.. Retraction plane in the tool axis

EH.. Height at which the machining starts

EG.. Clockwise (-1) or counterclockwise (1) motion

H.. File where the profile is programmed

N.. N.. First and last block of the profile

Q.. Advancement path

EE.. If programmed 0, the finishing machining is performed

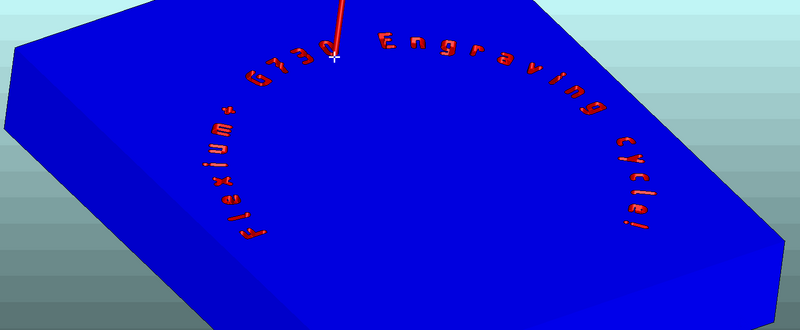

FXSO000701 Engraving Cycle (G730)

The G730 cycle is used to engrave characters from a string of text by interpolating the axes in the machine. The symbols that are available are the uppercase and lowercase letters (A-Z and a-z), numbers from 0-9 and some special characters. It is possible to write text in a straight line, with an inclination, or along the circumference of a circle with a certain radius R. Each letter can also be rotated by an additional angle (inclined character). This engraving cycle allows the end user to write some text (such as an ID, serial numbers, piece coding or date and time) on the workpiece without using a CAD/CAM system or any other software tool.

The syntax is:

G730 X.. Y.. Z.. R.. EL.. EA.. EI.. ER.. EH.. EX.. F..

The G730 engraving cycle has a full set of parameters to determine the position, layout and pattern of the text.

X.. X position of the SE (southeast, lower left) corner of the rectangle including the first letter

Y.. Y position of the SE (southeast, lower left) corner of the rectangle including the first letter

Z.. Z position of the engraving end (depth)

EL.. Height of the letters

F.. Machining feed

ER.. Retraction plane in the tool axis

EH.. Height at which the machining starts and all movements made between letters

R.. Radius of the circle on top of which the text is engraved

EA.. Angle of inclination of the text if straight line or angle of start in a circle

EI.. Space between characters (interspace)

EX.. Additional rotation of each character

EP.. Axial path

The most remarkable aspect of these new functions is that they both take the form of user-defined G cycle commands. This not only provides more flexibility, but also shows the performance of G functions for these types of applications. Of course, Flexium+ CNC has the necessary computing power for an integrated function, but a user-defined G function is just as efficient as an integrated one and offers in addition more customization options. Further information on G725 and G730 or other user-defined G functions can be found in the Flexium+ documentation or it can be obtained from your NUM NTC contact person, who will be happy to provide you with suggestions and solution support.

Please contact us for further information:

Contact

NUM AG

Battenhusstrasse 16

CH - 9053 Teufen

Telephone: +41 71 335 04 11

E-Mail: sales.ch(at)num.com