NUMgear Profile Grinding

The NUMgear Profile Grinding Technology Module for Involutes and Technology Module for Cycloids are set between user input from an HMI and the CNC. It takes the gear and tool data as input and calculates the shape of the gear tooth as well as the path of the dresser to create the corresponding grinding wheel.

NUMgear Profile Grinding Cycloid Technology Module

Most robotic systems demand smooth, precise and highly reliable low speed movement. Deriving that movement from a motor that runs optimally at, say, 1000 rpm necessarily involves some form of speed reduction gear box. Designers typically have a choice of two types of reduction gear box – planetary drives and cycloid drives.

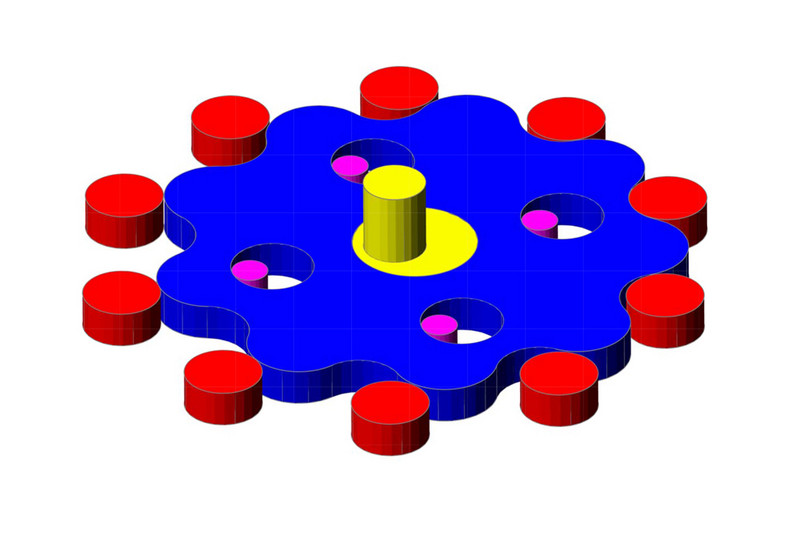

Planetary drives (or gear boxes) use one sun gear in the middle and planet gears around it, all imbedded into a ring. All of the gears, including the ring, have involute profiles. These types of drives are ubiquitous – they are used in a broad diversity of applications, including cars and other road vehicles, and are produced by virtually every gear manufacturer in the world.

The other type of speed reduction gear drive is the cycloid gear box. The input shaft drives an eccentric bearing that in turn drives the cycloidal disc in an eccentric, cycloidal motion. These gears do not require real gear wheels.

Gear boxes that use cycloid gears have very few moving parts and are some of the most efficient and reliable speed reducers available today. Single stator/rotor combinations can accommodate ratios as high as 300:1 and can provide efficiencies in excess of 93 percent.

Functions

The NUMgear Profile Grinding Cycloid Technology Module provides the following calculations:

- to get a gear tooth out of a few values (can be just the number of teeth of the stator, and the diameter)

- to get the path of the dresser so that the grinding wheel’s shape is exactly the negative of the tooth gap

For the ring, the gear is a cycloid. The external disk is a shortened epitrochoid.

Cycloid Profile Grinding is available for both internal and external gears. So both parts of a cycloid drive can be calculated using the NUMgear Cycloid Technology Module.

NUMgear Profile Grinding Involute Technology Module

The market for gears and gear boxes will still increase in years to come. With the rise of electric car drives, the demand might not be in the numbers, but in the quality of gears. Less noise, more compact, and better performance are the requests of the gear industry.

For mass production of involute gears Threaded Wheel Grinding is the obvious choice for external gears when it is all about speed.

For internal gears (ring gears), Profile Grinding is the only possibility.

Profile Grinding is slower, but allows for all possible variations of gear profile changes.

Functions

The NUMgear Profile Grinding Involute Technology Module provides the following calculations:

- to get a gear tooth out of a few values (can be just the number of teeth, module and pressure angle)

- to get the path of the dresser so that the grinding wheel’s shape is exactly the negative of the tooth gap

Please contact us for further information:

NUM AG

Battenhusstrasse 16

CH - 9053 Teufen

Phone: +41 71 335 04 11

E-Mail: sales.ch(at)num.com